Introduction

The lamb production system in WA is characterised by a large supply of lambs finished on green feed during spring and a reduction in supply through summer, autumn and winter.

The Investor-ready sheep feedlot report, commissioned by the Sheep Industry Business Innovation project, determined establishment costs, infrastructure requirements, considered environmental impact and effluent management assessments and conducted a benefit/cost feasibility study for low-input, large-scale (from 5000 to 50 000 head) commercial sheepmeat feedlots in WA. The full report can be accessed from the sidebar.

The project gained insight into potential management and operational issues through consultation with industry representatives including feedlot operators in WA and eastern states. Sheep feedlot design was examined, and WA restocker/feeder and trade lamb market prices, patterns, and relative values were analysed. The analysis assumed that the lambs were fed for eight weeks.

Video: report presentation

Geoff Duddy, of Sheep Solutions (New South Wales), prepared the report for the department. His presentation on his findings can be watched below.

Is feedlotting of sheep likely to be profitable?

Feedlotting profitability of sheep in the WA market was estimated to be generally negative or low, based on the input values analysed and regardless of feedlot size or throughput.

Under the scenarios and systems analysed, the greatest influence on profit was the restocker/feeder lamb starting value relative to the trade lamb values. The purchase price of the lambs needed to be 86% or less of the sale price for profits to be possible.

The profitability of finishing lambs is heavily influenced by:

- the value of restocker/feeder lambs relative to the finished trade lambs

- throughput, with operations finishing lambs at or close to their maximum annual throughput having lower depreciation on capital ‘cost’ and greater profit margins

- the timing of purchase and marketing of the finished lamb.

The profitability of finishing lambs is also influenced to a lesser degree by:

- feed prices

- establishment cost

- operational scale, with larger operations likely to return greater profits per lamb than smaller (5000-10 000) systems.

Analysis of historical saleyard prices found that there were strong seasonal price patterns. If forward contract prices are unavailable, historical price variation could be used to estimate finished lamb values from the known purchase price of restocker/feeder lambs and determine likely profitability.

Price patterns indicated that purchasing restocker/feeder lambs during winter to finish in a feedlot was risky. Feedlot finishing of mutton would have limited profitability other than prior to the winter price peak, while the relatively high variability of Merino lamb prices made it difficult to pre-determine likely profitability.

Variations in starter lamb values relative to finished lamb returns represent a threat to feedlot profitability that could be reduced if processors introduced a strong forward pricing mechanism.

Is it better to fill the feedlot once or keep it full year-round?

A 5000-head system might finish 5000 lambs a year (capacity) up to 43 333 a year (maximum throughput). Maximising lamb throughput was more profitable than finishing to feedlot capacity, because the fixed costs were spread over a greater number of lambs.

Increasing throughput significantly reduced depreciation cost on capital when costed as a dollar per lamb value. It also produced higher profit margins (or lower losses), and reduced margins between ‘capacity’ and ‘maximum’ profit range as operational size increased.

How is feedlot profitability affected by changes in the prices for feeders, trade sheep or the ration?

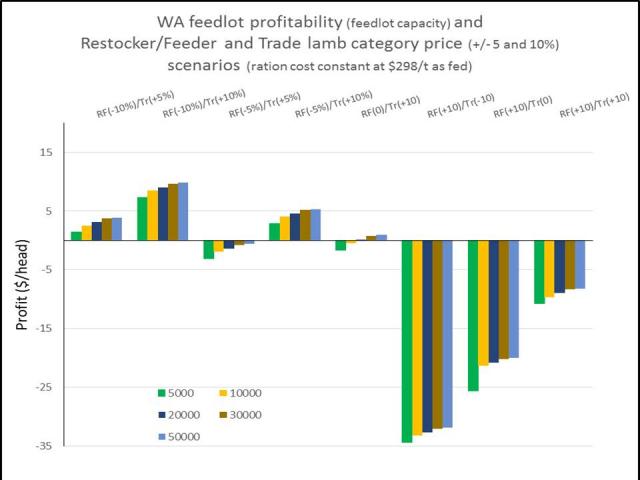

Various feedlot scenarios were developed around a detailed 5000-head capacity feedlot model farm unit. Economies of scale and increased efficiencies were factored into larger operations as a 2.5% reduction in capital costs per 5000-head capacity increase.

A sensitivity study examined the amount that prices of restocker/feeders, trade lambs and the ration could change and the enterprise still make a profit.

Examination of historical seasonal prices had established, relative to the average, the following historical peaks and troughs:

- restocker/feeder prices +7% (April) and -10% (November)

- trade lamb prices +11% (July) and -17% (November)

For the study, average 2017 WA prices for restocker/feeder and trade lambs per head were used as base costs, and varied by +/-5% and +/-10% to simulate price variability.

The analysis showed that profit margins from 10 cents (c)/head to $14.80/head were possible based on the input values analyzed, provided the relative price in cents per kilogram (c/kg) of the restocker/feeder was 86% or less of the trade lamb price.

| Profit | Change on base restocker/feeder price | Change on the base trade price | Feedlot size |

|---|---|---|---|

| 10c/head | 0% | +10% | 20 000-head at capacity (finishing 20 000 a year) |

| $14.80/head | -5% | +10% | 50 000-head at maximum throughput annually (finishing 433 333 lambs a year) |

Movements in ration cost of +/-5% had only minor impacts on profitability.

How should the industry develop large-scale feedlots in WA?

It is recommended for future development of large-scale feedlot systems within Western Australia that:

- a thorough cost/benefit analysis be conducted prior to feedlot development regardless of scale

- any feedlot system budgeting analysis should consider restocker/feeder to trade lamb price ‘relativities’, and lamb throughput should be maximised to spread fixed costs over more lambs

- greater emphasis be placed on modifying lamb supply patterns to minimise seasonal price variations

- consideration be given to the:

- development of producer run smaller scale (3000 to 5000 head) feedlot systems with minimal infrastructure cost, reducing operational and financial risk

- development of small (3000 to 5000 head) to medium (10 000 to 20 000 head) scale producer/feedlotter alliances to ensure continuity of supply and quality control within producer operated systems

- development of medium scale (10 000 to 20 000 head) feedlot systems supported by processor bodies responsible for coordinating lamb supply, reducing operational and financial risk

- development of medium scale (10 000 to 20 000 head) feedlot systems paid a management fee to finish lambs sourced/supplied by processor bodies, reducing operational and financial risk

- development of large-scale (30 000+ head) feedlot systems by processor bodies who are responsible for coordinating lamb supply and operational/financial risk

- development of processor/feedlotter producer alliances based on contract backgrounding of lambs prior to feedlotting. Such alliances would be of greatest benefit during the spring lamb price trough period when a majority of annual lamb purchases could be made and stubble, summer forages, and perennials could be utilised.

Conclusions

- Analysis indicated that feedlotting profitability is generally negative or low, based on the input values analysed and regardless of feedlot size or throughput.

- Small profits were possible when the restocker/feeder price (c/kg) was 86% or less of the trade price eight weeks later.

- Changes in ration cost have a smaller impact on profitability than the lamb purchase and sale prices.

- Once restocker/feeder values are known, historical seasonal price patterns are a useful tool to estimate the value of finished lambs if forward contract prices are unavailable.