Costs of owning a harvester

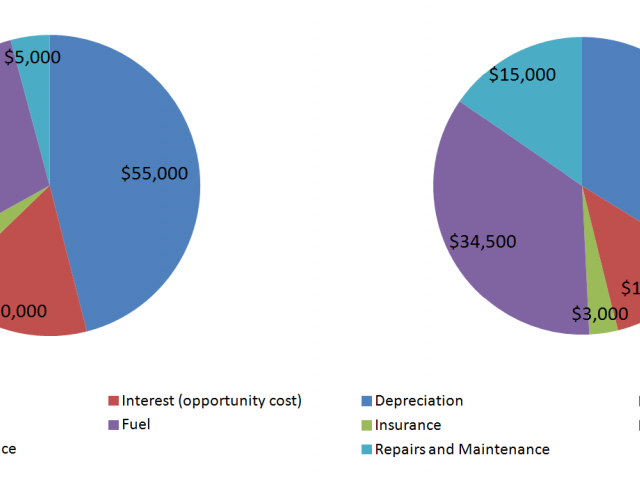

Owning a harvester typically incurs large fixed costs. Although a harvester is often only used for two months of the year, up to 90% of its cost can be fixed in the form of depreciation, finance/opportunity cost of capital and insurance. Operation and maintenance costs are minor in comparison. In general, the size of the cropping program will often dictate the required size of the harvester and therefore the magnitude of the overhead (fixed) costs.

Estimates of the annual cost of owning harvesters valued at $500 000 or $300 000 are given in Figure 1 below. There is provision for repair and maintenance costs for the harvester valued at $500 000 but if the harvester is new, some repair costs may be covered under warranty. The annual cost of a havester valued at $500 000 is around $120 000 compared to $98 000 for a havester valued at $300 000.

Harvest option analysis

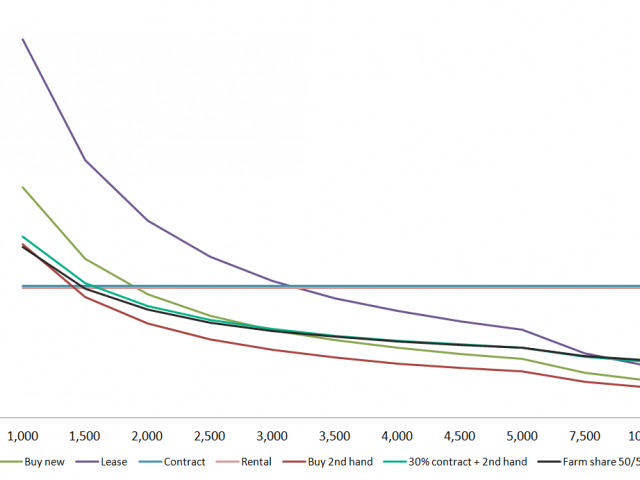

To understand how the cost of harvest options varies across crop acreage we have analysed a number of scenarios as outlined below. We have incorporated additional crop insurance into options where the farm enterprise is exposed to more weather risk due to harvest delays. Costs are calculated on an annual basis. The options are:

- Buy a new harvester for $500 000 including 4% real interest charge for the opportunity cost of capital

- Hire purchase lease for a new harvester valued at $500 000 at 12% pa over a five year term with nil residual

- Employ contractors - the cost in WA varies between $37-50/ha (excluding fuel) depending on cropping conditions and includes chaser bin. We assume $42/hr and include 33% crop insurance to allow for potential delays in harvest

- Rent a harvester valued at $500 000 on hourly rate charged at 0.1% RRP and include 33% crop insurance for potential delays in harvest

- Buy a second hand harvester at 60% of new price ($300 000)

- Share a new harvester with a neighbour on a 50/50 basis, and include 100% crop insurance

- Own a second-hand harvester and contract harvest 30% of the crop area

Based on our assumptions our analysis suggests the annual cost of contract harvesting is the lowest annual cost option for cropping programs less than 1500ha. For crop areas greater than 1500ha the cost of owning a harvester valued at $300 000 is the lowest cost option and varies from $50/ha for 1500ha to $12/ha for 10 000ha.

This is not prescriptive and should be viewed as a guide only. There is also the option of smaller operators purchasing older second-hand harvesters which is not included in our analysis. Furthermore, other factors need to be taken into consideration including risk of crop damage, price spreads for grain quality and yield, which can be influenced by contractor efficiency. We have explored the potential financial impact of these factors in Table 1.

| Grade damage ($/t) | Contractor efficiency 105% | Contractor efficiency 102% | Contractor efficiency 100% | Contractor efficiency 98% | Contractor efficiency 95% | Contractor efficiency 90% |

|---|---|---|---|---|---|---|

| 0 | -23 | -9 | 0 | 9 | 23 | 46 |

| -10 | -2 | 11 | 20 | 29 | 42 | 64 |

| -25 | 30 | 42 | 50 | 58 | 71 | 91 |

| -50 | 82 | 93 | 100 | 107 | 118 | 136 |

| -75 | 135 | 144 | 150 | 156 | 166 | 181 |

| -100 | 187 | 195 | 200 | 205 | 213 | 226 |

Our analysis shows that if a contractor operates at 95% efficiency (that is, losing 5% of the potential grain yield during harvest), it costs the farmer an additional $23/ha. This effectively increases the contracting cost to around $68/ha. Alternatively, if the contractor is 5% more efficient in taking off the crop (for example, due to newer equipment), it could translate into a $23/ha saving, effectively lowering the contracting cost to $22/ha. The cost of a downgrade to quality can be significant and depends on the extent of the downgrade margin which can be large in some seasons. In season 2011, for example, downgrades from milling wheat to general purpose cost between $20-40/tonne depending on what variety was grown, whereas the downgrade to feed typically cost $80/tonne in 2011.

The cost of a quality downgrade is shown in Table 1. If, for example, a weather event causes the crop to be downgraded by $50/tonne, then based on a 2t/ha yield this translates to a cost of $100/ha, which is more than double the cost of employing a contractor. In this instance, the farmer would have been $50/ha better off had they also employed contractors in the early part of harvest and avoided the impact of the weather event.

Another issue at harvest is the consequence of bottlenecks in the supply chain, particularly in seasons with above average yields. When regional grain production is very large, contractor harvesters, rental equipment and transport trucks can be in short supply and the turnaround time at the grain bins is often significantly longer. If it appears the season will result in delays in turnaround time and there is a risk of an adverse weather event and possible downgrade, we recommend farmers consider investing in additional on-farm storage. Similar to the supplementary contracting scenario, a downgrade in quality can cost a lot more than the investment in additional storage such as silos, sausage bags or sheds.

In summary, when considering harvest options, farmers should not only consider the capital cost of the equipment but also consider their seasons, the risk of delays and downgrades and assess the overall financial impact of each harvest option. In general, be aware of the often high fixed costs of buying a new harvester, match it with the ability of the farm enterprise to absorb this overhead and also consider the opportunity cost of alternative uses of the capital. Also, assess the risk of a weather events leading to a downgrade.

For further reading refer to Machinery purchasing decision support for broadacre growers.