Types of herbicides

- Translocated herbicides move to the site of action via the transport mechanisms within the plant; the xylem and phloem. The xylem transports water and nutrients from the soil to growth sites and the phloem transports products of photosynthesis (for instance, sugars) to growth and storage sites. It may take up to two weeks for symptoms to develop on the target weeds depending on herbicide rate, conditions and species.

- Contact herbicides have limited movement within the plant, so complete coverage of the target is critical. Compared to translocated herbicides (for example, glyphosate), contact herbicides (for example, paraquat, oxyfluorfen, diquat and bromoxynil) tend to show symptoms rapidly, usually within 24 hours.

- Selective herbicides will kill target weeds and not desired plants (the crop or pasture) when applied at a specified application rate.

- Non-selective herbicides (also called knockdown herbicides) such as glyphosate or paraquat will damage most plants.

- Residual herbicides remain active in the soil for an extended period of time (months) and can act on successive weed germinations.

- Non-residual herbicides, such as the non-selective paraquat and glyphosate, have little or no soil activity and are quickly deactivated in the soil. They are either broken down or bound to soil particles, becoming less available to growing plants. They also may have little or no ability to be absorbed by roots.

- Post-emergent and pre-emergent are terms that refer to the target and timing of herbicide application. Post-emergent refers to foliar application of the herbicide after the target weeds have emerged from the soil, while pre-emergent refers to application of the herbicide to the soil before the weeds have emerged.

- Herbicide mixtures and sequential applications involve the application of more than one herbicide, usually to increase the spectrum of weed species controlled but also for resistance management. A mixture involves the application of multiple products in a single application. Where herbicides are antagonistic and cannot be mixed together in a single tank, they are applied sequentially.

Knockdown herbicides for fallow and pre-sowing control

Knockdown herbicides (or non-selective) kill all plants when used in sufficient quantities, under suitable environmental conditions.

Benefits

- Knockdown herbicides effectively kill weeds and are cost-effective.

- Use of knockdown herbicides can improve the timeliness of sowing.

- Use of knockdown herbicides rather than cultivation will reduce the risk of erosion, improve soil structure and improve plant available soil water content.

Issues

- Consider the suitability of herbicide use for fallow or pre-sowing weed control by assessing environmental conditions.

- Stressed weeds will not be adequately controlled by knockdown herbicides.

- Overuse of knockdown herbicides will select for resistance.

- Suitable meteorlogical conditions for spraying can be limited, especially for weed control over the summer fallow.

Double knockdown

'Double knock' refers to the sequential application of two weed control tactics applied in such a way that the second tactic controls any survivors of the first tactic. A common combination is glyphosate followed by paraquat or paraquat/diquat.

Benefits

- Double knockdown delays or prevents the development of glyphosate resistance.

- Using a double knockdown strategy reduces the number of (potentially resistant) weeds to be controlled in crop.

- Excellent weed seedling control is achieved.

Issues

- Glyphosate should be applied first, followed by paraquat or paraquat/diquat.

- The timing between applications will vary depending on the main target weed species.

- Consider the main target weed species when choosing what herbicides to use in the double knockdown.

- Double knockdown is more expensive than a single herbicide application.

- Seasonal conditions will influence the scale of on-farm implementation (as a double knockdown takes more time than a single application).

Pre-emergent herbicides

These herbicides control weeds between radicle (root shoot) emergence from the seed and seedling emergence through the soil. Some pre-emergent herbicides may also provide post-emergent control.

Benefits and issues

- The residual activity of pre-emergent herbicides controls the first few flushes of germinating weeds while the crop or pasture is too small to compete.

- Good planning is needed to use pre-emergent herbicides as an effective tactic. It is necessary to consider weed species and density, crop or pasture type, soil condition and rotation of crop or pasture species.

- Soil activity and environmental conditions at the time of application play an important role in the availability, activity and persistence of pre-emergent herbicides.

- Both the positive and negative aspects of using pre-emergent herbicides should be considered in the planning phase.

Selective post-emergent herbicides

These products control weeds that have emerged since crop or pasture establishment and can be applied with little damage to the crop or pasture plants.

Benefits

- Post-emergent herbicides give high levels of target weed control with the additional benefit of improved crop or pasture yield.

- Observations made just prior to application allow fine-tuning of herbicide selection to match weeds present in the paddock.

- Timing of application can be flexible to suit weed size, crop growth stage and environmental conditions.

- Some post-emergent herbicides have pre-emergent activity on subsequent weed germinations.

Issues

- Use careful consideration when selecting the best post-emergent herbicide to use in any one situation.

- Application of post-emergent herbicides to stressed crops and weeds can result in reduced levels of weed control and increased crop damage.

- Crop competition is important for effective weed control using selective post-emergent herbicides.

- The technique used for application must be suited for the situation in order to optimise control.

- Always use the correct adjuvant to ensure effective weed control.

- Selective post-emergent herbicides applied early and used as a stand-alone tactic have little impact on the weed seedbank.

- Choose the most suitable formulation of herbicide for each situation.

- The effectiveness of post-emergent herbicides is influenced by a range of plant and environmental factors.

Herbicide uptake by plants

Foliar applied herbicides

Effectiveness is influenced by the distribution/composition of the spray droplets and the characteristics of the leaf surface on which the spray is deposited.

Herbicides in the soil

Both foliar and soil applied herbicides may be present in the soil and absorbed through plant roots.

Root absorption

Water soluble herbicides are absorbed in water through root hairs and the area just behind the root tip.

Coleoptile and young shoot absorption

Some herbicides (such as triallate or trifluralin) act mainly through root uptake with some shoot uptake. These products can be volatile and need to be absorbed quickly to be effective. Non-volatile shoot uptake herbicides (that is, diflufenican and metolachlor) rely on a moist soil surface for best efficacy.

Stressed weeds

Stressed weeds are harder to kill than healthy, actively growing weeds. Stress is caused by lack of moisture, lack of oxygen due to water logging, extremes of temperature, nutrient deficiencies, insect pests, disease, a sublethal dose of herbicide from prior applications or residues and mechanical damage (that is, from tillage, slashing or grazing). Once a weed has been subject to stress it will not be adequately controlled by rates of herbicide that would otherwise be sufficient to control an unstressed weed, even after the stressed weed has apparently recovered from the stress. Additives may help control stressed weeds, but can be unpredictable.

Movement of herbicides in the environment

Herbicides have the capacity to move in the environment away from the target area, and to cause damage to non-target plants and animals. There are management options to reduce the possibility of this happening.

Herbicides in plants

A certain proportion of any selective herbicide applied to a crop will be absorbed by crop plants and by tolerant weeds rather than by those weeds which the herbicide is intended to control. These plants are able to tolerate the herbicides because various enzymes within them metabolise the chemical before it can cause permanent damage. Thus this portion of the herbicide is removed from the environment and destroyed.

Susceptible weeds are not able to metabolise the herbicide, at least not quickly enough to avoid being killed. As the plant dies however, its cells rupture and release a range of oxidising enzymes. These enzymes destroy much of the plant tissue, and the herbicide as well.

Thus this fraction of the herbicide also is removed from the environment.

Herbicides in the atmosphere

Most herbicides in the atmosphere get there as a result of fine spray droplets not settling but drifting and finally evaporating. All herbicides have the potential to do this. Some are also sufficiently volatile to enter the atmosphere by evaporating (volatilising) from the surface of sprayed plants or from the soil eg. Trifluralin and the volatile ester formulations of 2,4-D.

The potential danger herbicides in the atmosphere pose to nearby plants is only short term. Ultraviolet light striking a herbicide molecule has sufficient energy to disrupt some of the bonds between its constituent atoms destroying the molecule. Rates of breakdown for any compound will depend upon the intensity of sunlight.

Degradation of herbicides in soil

Many herbicides that are used in one year of a typical cropping rotation have the potential to damage crops grown in other years of that rotation. Fortunately, in an average year these herbicides are broken down (degraded) into harmless compounds by a combination of biological and chemical processes and do not cause any problems for the crops.

From the moment a herbicide enters the soil system, it begins to break down. Most of this degradation is due to the action of microscopic living organisms. These organisms break down the organic material in the soil to provide the energy they need to live (it is their food supply). When a herbicide is added to their environment, it also becomes a potential food supply. Some herbicides are also prone to chemical reactions which alter their structure and render them non-phytotoxic.

These degradation processes all depend upon soil temperature and moisture levels. They increase in direct proportion to soil temperature, and begin when the moisture level rises above the wilting point. Extra moisture increases the rate of degradation but not by as much as higher temperatures.

Triazines (atrazine and simazine), sulfonyl ureas (Chlorsulfuron, Triasulfuron etcetera), imidazolinones (Spinnaker®, Raptor®, OnDuty®, Midas®) are all candidates for carryover. All other things being equal, imidazolinones will be more persistent on acid soils and sulphonyl ureas on alkaline soils. Triazines are very slightly more persistent on alkaline soils.

Any paddock where any of these products were applied in June or later (especially in a year with low rainfall after application) should be regarded as having potentially damaging levels of residues, and so should areas of earlier applications if there were significant periods when the soil surface was dry.

Movement of herbicides by soil or leaching

- Soil may be left bare as a result of cultivation for cropping, or by destruction of vegetation by herbicides on firebreaks and roaded catchments. If wind or water moves this soil, any herbicides in the soil will be moved also, and may damage desirable vegetation wherever it settles.

- As rain water moves down the soil profile from the surface, herbicides in the soil will move with it to some extent. This leaching is a dynamic process, whereby the herbicide alternates between being dissolved in the water and therefore moving with it, and being adsorbed onto soil particles and therefore immobile. The rate of movement of any herbicide down the profile therefore depends on its solubility in water and the strength with which it absorbs onto soil particles.

- Later in the season, when net water movement is back toward the drying surface soil, it is possible to have previously leached herbicide moving up from sub-soil with this reverse water flow.

Residue effects

Triazine residues will vary in the damage they cause according to the seasonal conditions. Residue effects will be much less when the season start is uniform and rainy compared to dry. Root disease will exacerbate the effect of triazine residues as the young seedlings cannot grow away from the residues which are concentrated in the cultivation layer.

Sulfonyl urea and imidazolinone residues are less affected by soil moisture as they are more soluble. The first effect of the sulfonyl ureas is to prune roots. Be careful in duplex soils that have sand over alkaline clay. The sulfonyl ureas can leach down to the clay where they will be more persistent due to the high pH.

Herbicide drift

Herbicide drift is the movement of pesticide away from the target area in the atmosphere. The three main forms of drift are droplet drift, vapour drift and particulate drift. Droplet drift is the main cause of off-target damage.

Spray emerging from a boom breaks up into droplets of varying size. Larger droplets fall onto the target area, while the smallest droplets may remain in the air.

Because droplet drift usually disperses as it moves away from the sprayed area, the type of crop damage it causes in adjoining areas is easily recognised. That part of the sensitive crop which is closest to the sprayed area is severely damaged but damage decreases away from the severe zone.

Vapour is produced by evaporation from the droplets when they leave the boom and from the target surface after spraying.

Like droplets, vapour disperses rapidly as it is carried away from the target area. The vapour will remain suspended in the air unless the contaminated air is forced back to ground level where it may damage growing plants.

Vapour can drift for long distances, and the characteristic feature of vapour drift damage is that no clear damage gradients can be seen. Damage, which is generally mild but widespread, is usually caused by a large body of contaminated air several square kilometres in size.

To understand damage caused by drift of herbicides there are four key aspects that require understanding:

Production of driftable sized particles

Most agricultural herbicides are applied as fine droplets produced by hydraulic nozzles on boom sprays, mostly set up to deliver droplets in the 150-300µm range. Droplets from 100-200µm in diameter usually stick to the first surface they encounter but droplets larger than 500µm are likely to bounce off leaves and end up on the soil or lower canopy and droplets smaller than 50µm are likely to float around the target plant and drift off. The smaller droplets provide better coverage which is important when the target plant is small, when the herbicide is poorly translocated or when low carrier volumes are used. The larger droplets result in greater interception or less drift, but the poorer coverage may need to be compensated for by using translocated herbicides or higher carrier volumes.

Most commercially available nozzles produce a range of droplet sizes so there is usually a proportion of very fine droplets that may drift. For emulsifiable concentrate sprays, drift reducing agents such as Nalcotrol® may reduce drift. For aqueous sprays the addition of a drift reducing agent may increase the production of droplets that are less than 100µm diameter and cause greater drift. Also, shear stresses in recirculating pumps (especially centrifugal pumps) can reduce the effect of polymer drift reducing agents.

Transport of herbicide away from the target area

Under the influence of gravity, all droplets fall at a speed called sedimentation rate. Large droplets fall faster than small droplets. Within a few centimetres of the nozzle the movement of most droplets is determined by gravity, their buoyancy and wind. The higher the droplet is released, the further it will move away from the target area because the wind speed is slower close to the ground and there is more time for the wind to move the droplet before it lands. Therefore, the amount of pesticide that drifts off target is closely related to the boom or flying height. Halving the height of the boom above the target will reduce drift by about 60%. In situations where drift can cause problems the boom should be operated at the lowest height possible for the nozzles and spacing.

Decreasing the nozzle spacing will allow the boom to be operated at a lower height. Large droplets contain more herbicide but they tend to land close by, whilst small droplets contain less herbicide but are moved over greater distances by the wind and are more likely to be affected by turbulence that may carry them upwards. (Note: About 2-10% of spray volume of aqueous formulations will be in drift-prone droplets - less than 100µm diameter - with normal flat fan or cone nozzles on aircraft and less on boom sprays. Emulsifiable formulations of herbicides will produce about twice as many droplets in this size range with the same equipment).

The size of the area sprayed also affects the amount of herbicide leaving the target area because successive runs contribute to drift. As small droplets drift away from the sprayed area they normally disperse to non toxic concentrations within 100-200 metres downwind. Under low level temperature inversion conditions the droplets may be trapped in a layer of cool air close to the ground and move greater distances at higher concentrations. These conditions are most likely to occur when there is little or no wind, clear skies, the weather is influenced by a high pressure system and the ground is cooler that the surrounding air in the evening and may last until the sun warms the ground on the following day or until the wind speed increases (most claims for drift damage are associated with inversions). This can be made worse by valleys that can channel drift laden air for a kilometre or more.

Interception or absorption of the transported herbicide by the off target species

As droplets leave the target area they usually decrease in size as the carrier evaporates. This affects the deposition on off-target plants and generally reduces the damage that would otherwise be predicted by drift. Damage is a function of the number of droplets impacting on the plant multiplied by the concentration of herbicide in the droplet. Small droplets that have been produced by the evaporation of large droplets carry more herbicide than small droplets produced at the nozzle.

Dose response curve of the herbicide for the affected species

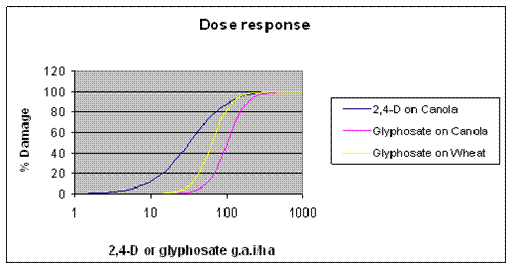

The dose response curve for many plants to herbicides is a logistic curve as shown below. At very low doses there is no significant effect on the plant. As the dose of herbicide increases the amount of damage increases until at high doses the plant dies and increasing the dose will have no further effect.

The graph also shows that wheat is damaged more than canola by low doses of glyphosate and the no-effect-level (NOEL) is around 10 grams of active ingredient per hectare (g.a.i/ha) for wheat and 25g.a.i./ha for canola. For canola, the dose required to kill it is similar for glyphosate and 2,4-D. However, because the slope of the dose response curve for 2,4-D is less that for glyphosate, the NOEL for 2,4-D on canola is much less that the NOEL for glyphosate. This means that canola crops are more tolerant to glyphosate drift than they are to 2,4-D drift.

Drift can be reduced by increasing the droplet size, followed by reducing boom height, followed by application at reduced wind speeds.

Environmental conditions and windspeeds affecting spraying operations

The following environmental conditions at the time of spraying will influence the effectiveness of the spraying operation:

- Weather: High temperatures, low humidity, high delta T and wind speeds less than 3km/h or greater than 15km/h during spraying may mean a loss of herbicide through drift or evaporation;

- Plant stress: Lower levels of control often occur when weeds are under environmental stress when sprayed. For example, for glyphosate to work it must be translocated around the plant to its site of action and weeds need to be actively growing (not stressed) to maximise the uptake and translocation. Stress may be caused by environmental conditions such as drought, water-logging or frost;

- Rainfall: Rainfall shortly after spraying may wash the herbicide off the plants before it has had time to act.

Wind speed is the main factor to be considered at the time of spraying for winter crops. The following points should be followed in windy conditions:

- Read the herbicide label or seek advice. Take particular note of the toxicity of the herbicide and any adverse effects it will have on other crops, trees, wildlife or human health.

- Assess possible damage downwind from the paddock to be sprayed. An advantage of spraying in high wind speeds is that you know the direction in which the spray will drift. Drift can also be a problem in very light winds, particularly if there is a temperature inversion.

- Adopt methods to reduce drift. For example, using low pressure nozzles or low nozzle height. Remember that no current method eliminates drift.

- Assess the risks and decide if they are worth taking. For example, if you are spraying a selective herbicide in wheat and down-wind there are other wheat crops, you are probably fairly safe to spray in a strong wind. On the other hand, if you are spraying knock-downs and down-wind there is a belt of new trees you have been trying to establish, wait for more favourable spraying conditions.

- Do not spray if the maximum wind speed is greater than the speed at which you are spraying. If the wind speed is greater than your speed of travel, you risk coming into contact with the drift when spraying with the wind behind you.

Use a small hand-held anemometer (used to measure wind speed and is relatively cheap and a good investment when spraying). Wind speed is variable, so when deciding whether to spray, read the maximum wind speed during a wind gust. The average wind speed will be lower than this figure, so allow a margin of safety. Wind speed and direction should be recorded for all spraying.

Damage caused by herbicide drift

Herbicide drift can cause significant damage to crops. Below are four ways that damage can occur.

Production of driftable sized particles

Most agricultural herbicides are applied as fine droplets produced by hydraulic nozzles on boom sprays, mostly set up to deliver droplets in the 150-300µm range. Droplets from 100-200µm in diameter usually stick to the first surface they encounter but droplets larger than 500µm are likely to bounce off leaves and end up on the soil or lower canopy and droplets smaller than 50µm are likely to float around the target plant and drift off.

The smaller droplets provide better coverage which is important when the target plant is small, when the herbicide is poorly translocated or when low carrier volumes are used. The larger droplets result in greater interception or less drift, but the poorer coverage may need to be compensated for by using translocated herbicides or higher carrier volumes. Most commercially available nozzles produce a range of droplet sizes so there is usually a proportion of very fine droplets that may drift.

For emulsifiable concentrate sprays, drift reducing agents such as Nalcotrol® may reduce drift. For aqueous sprays the addition of a drift reducing agent may increase the production of droplets that are less than 100µm diameter and cause greater drift. Also, shear stresses in recirculating pumps (especially centrifugal pumps) can reduce the effect of polymer drift reducing agents.

Transport of herbicide away from the target area

Under the influence of gravity, all droplets fall at a speed called sedimentation rate. Large droplets fall faster than small droplets. Within a few centimetres of the nozzle the movement of most droplets is determined by gravity, their buoyancy and wind.

The higher the droplet is released, the further it will move away from the target area because the wind speed is slower close to the ground and there is more time for the wind to move the droplet before it lands. Therefore, the amount of pesticide that drifts off target is closely related to the boom or flying height. Halving the height of the boom above the target will reduce drift by about 60%. In situations where drift can cause problems the boom should be operated at the lowest height possible for the nozzles and spacing. Decreasing the nozzle spacing will allow the boom to be operated at a lower height.

Large droplets contain more herbicide but they tend to land close by, whilst small droplets contains less herbicide but are moved over greater distances by the wind and are more likely to be affected by turbulence that may carry them upwards. (Note: About 2-10% of spray volume of aqueous formulations will be in drift-prone droplets - less than 100µm diameter - with normal flat fan or cone nozzles on aircraft and less on boom sprays. Emulsifiable formulations of herbicides will produce about twice as many droplets in this size range with the same equipment).

The size of the area sprayed also affects the amount of herbicide leaving the target area because successive runs contribute to drift.

As small droplets drift away from the sprayed area they normally disperse to non toxic concentrations within 100-200m downwind. Under low level temperature inversion conditions the droplets may be trapped in a layer of cool air close to the ground and move greater distances at higher concentrations. These conditions are most likely to occur when there is little or no wind, clear skies, the weather is influenced by a high pressure system and the ground is cooler that the surrounding air in the evening and may last until the sun warms the ground on the following day or until the wind speed increases. (Most claims for drift damage are associated with inversions). This can be made worse by valleys that can channel drift laden air for a kilometre or more.

Interception or absorption of the transported herbicide by the off target species

As droplets leave the target area they usually decrease in size as the carrier evaporates. This affects the deposition on off-target plants and generally reduces the damage that would otherwise be predicted by drift. Damage is a function of the number of droplets impacting on the plant multiplied by the concentration of herbicide in the droplet. Small droplets that have been produced by the evaporation of large droplets carry more herbicide than small droplets produced at the nozzle.