This activity is covered by legislation

An owner or occupier of land must give at least 90 days notice to the Commissioner of Soil and Land Conservation of an intent to drain subsurface water to control salinity and discharging that water onto other land, into other water or into a watercourse, even on the same property. The notice must be in writing using the notice of intent to drain or pump (NOID) form. Principles and guidelines for inland drainage are covered in the Policy framework for inland drainage.

How does pumping work?

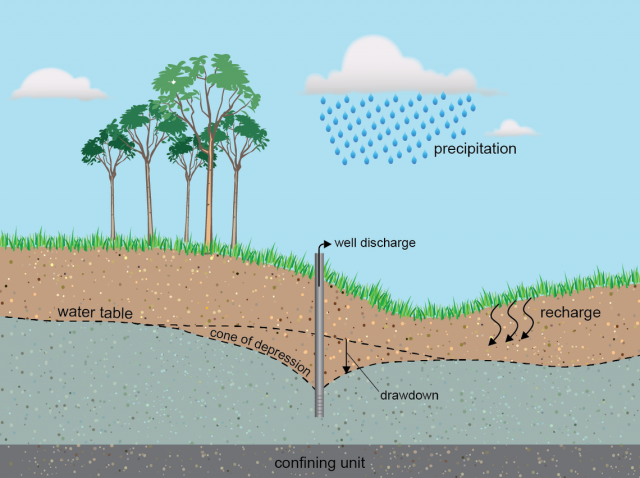

Pumping groundwater from a bore (or well) draws down the watertable in a cone of depression (Figure 1 Source: USGS), which prevents the saline watertable from affecting the surface soil within the drawdown area.

And does it reduce salt-affected surface soil?

During the 1980s and early 1990s, pumping systems were established throughout the grainbelt with mixed success. The least effective sites were in low-permeability groundwater systems, especially in areas with overlying clay-rich soils. Pumping was most effective in permeable aquifer systems discharging to the surface.

In optimum situations, pumping can have a 10–20 hectare (ha) impact zone for low yielding systems (less than 1 litre per second (L/s), which is about 85 cubic metres per day) and range to a maximum of 400ha for higher yielding, multi-well systems (about 10L/s from several wells).

Where pump yields are lower or conditions are less favourable (e.g. clay-rich subsoils, low yielding or multi-layered aquifers), the zones of influence are significantly reduced.

What you need to know before pumping groundwater

- You must give at least 90 days notice to the Commissioner of Soil and Land Conservation and receive a notice of 'no objection'.

- To be effective, groundwater pumping requires an unconfined aquifer with a deep, highly conductive profile. You may need several test bores before finding a good pump bore site.

- Pumping causes a cone of depression (Figure 1) in the watertable: the area to be protected needs to be identified and the pump system designed to provide this protection.

- Multiple production bores may be needed to extend the area of watertable drawdown.

- Groundwater pumping discharges saline water onto the surface and this can cause problems. See legislation.

- Saline discharge must go to a safe release point. Highly saline water can be released into an evaporation basin or pond. See legislation.

- After depressing the watertable, salt in the surface and shallow subsurface soils needs to be leached below the root zone to allow good plant growth.

- Pump, power and maintenance costs are high for most pumping systems.

- Wind and solar powered pumping are more cost-effective compared to electrical and liquid fuel powered pumps.

Locating bores and pumps to be effective

We recommend site investigation by a hydrologist to determine the:

- nature of the aquifer

- expected yield

- water quality

- disposal options

- the most appropriate pumping system

- pump location/s: bores and pumps should be located within the affected area and upslope of any geological 'blocking' structure.

Locate the high yielding aquifers

Groundwater beneath much of the agricultural area is stored in a thin layer (maybe 2 to 20m) of gritty sand located just above the fresh bedrock. In valleys, alluvial sediments deposited by ancient rivers form the major aquifers.

Geophysics can help to locate high yielding zones, such as palaeochannels, within major valley sediments. In weathered bedrock aquifers, high yielding bores are most likely where the aquifer is thickest, which is often in the saline areas and well away from outcropping bedrock.

Small aquifers are also found in sands overlying the deep sediments in valleys or weathered bedrock on hillsides. Valley sediments and weathered zone aquifers are the 2 main aquifer types that may be pumped to help manage salinity.

In higher rainfall areas, yields may be greater adjacent to quartz and dolerite dykes and in faults. Permeabilities of 2 to 5 times those of the surrounding materials have been measured in some structures.

Specialist information and advice

Hydrogeological maps prepared by the Department of Water and Environmental Regulation (DWER) for the coastal plain, and some southern agricultural areas (south of a line from Harvey to Lake Grace and east to Esperance) show the aquifer types and give a guide to estimated yield and quality. The maps provide a regional overview of likely aquifer conditions and are only a guide for site investigations.

You can get advice from local drilling contractors, groundwater consulting firms, pump manufacturers and regional DPIRD hydrologists.

Choose a suitable pumping system

Choose from the 3 pumping systems (Table 1).

| Pump type | Power supply | Comments |

|---|---|---|

| Submersible | Mains electric or solar | Depend on proximity of power, pumping rate required and total working head. Typically require high yielding aquifers (more than 2–3 L/s). |

| Compressed air systems | Mains electric or solar | As above, air compressors can be remote from the site. Water can be reticulated 5–10 km from the power source. Typically pump at rates less than 2 L/s. |

| Piston, rotor | Wind, solar or mains electric | Low yielding system |

Design your pumping system

When designing a pumping system, you need to assess the:

- location of the nearest source of mains power

- aquifer conditions – long-term yield, total working head

- bore construction – casing type, sediment load

- water quality – iron bacteria, silica and other contaminants likely to reduce performance

- disposal options.

Salinity management usually requires a whole-farm approach with a combination of treatments: pumping is a short-term treatment that can provide conditions to establish plant-based treatments or to give rapid protection to high value assets. Pumping provides a relatively small area of drawdown, and requires ongoing investment.

Pumping could provide water – depending on the salt content – for livestock, domestic or industrial purposes. In many cases, pump water will need desalination for livestock and other purposes.

High silica and iron bacteria in groundwater can cause significant maintenance problems, particularly in some submersible and compressed air systems.

Submersible pumps may also have short life expectancy where groundwaters are highly saline or acidic. Copper or chlorine leaching systems can be used to manage iron bacteria.

Siphon and relief well systems may be used as an alternative to pumping systems. In areas with slopes greater than 2%, where groundwater pressures rise above the surface, siphon networks with a combined yield of more than 1 L/s have been found to lower watertables and dry out hillside seeps.

Install the bores for pumping

We recommend that you use an experienced and licenced contractor for this job. Even with the site assessment, not all bores are productive for pumping: there may be a need to drill more than 1 bore and this is an expensive option.

Pumping groundwater for asset protection

Pumping can be used to protect high value assets threatened by rising saline watertables, such as townsites, roads or railway lines. Pumping has the benefit of rapidly depressing threatening watertables without taking a lot of space. For instance, see:

- Merredin townsite groundwater pumping and desalination pilot project

- Groundwater pumping to prevent salinity at Bodallin (PDF)

Legal and environmental aspects

Common law governs the flow of surface water from artificial drains and underground water that is discharged into watercourses:

- Construct artificial drainage so that it does not have a detrimental effect on streams further down the catchment.

- Take reasonable steps to ensure the safety of other people and other people's property.

- To minimise the risk of legal action for subsequent damages, consider the effect that planned earthworks (construction and operation) may have on other people and seek written consent from any person that may be affected.

- Take due care during construction and maintenance to stop the loss of disturbed material from the site.

Under Regulation 5 of the Soil and Land Conservation Act 1945, the land owner or occupier proposing to 'drain or pump water from under the land surface because of salinity of the land or the water, and to discharge that water onto other land, into other water or into a watercourse' must notify the Commissioner of Soil and Land Conservation (the Commissioner) of that intent at least 90 days prior to discharging the water, using the notice of intent to drain or pump water (NOID) form.

For proposals to drain land within the Peel–Harvey Catchment, proponents must submit a notice of intent to drain or pump water (NOID) to the Commissioner at least 90 days before draining surface or subsurface water onto other land, into other water or into a watercourse

Interference with a watercourse in a proclaimed surface water management area is controlled under the provisions of the Rights in Water and Irrigation Act 1914 (WA).