The information in this page is only a guide – seek expert advice before planning, and use expert contractors for construction where necessary. Each landholder has a duty of care to make sure that flows from earthworks are not discharged indiscriminately on a neighbouring property and that stream flows are not significantly diminished or degraded.

See Conservation earthworks legal requirements of landholders for more information.

What is an 'excavated tank' or 'farm dam'?

Dams block an existing waterway, and earth tanks are an excavation into which water is diverted. This page only deals with excavated tanks, which can be hillside dams, excavated earth tanks, ring or turkey nest tanks.

An excavated tank is an earth structure on near-level land used to store water, in which part of the storage capacity is below ground level. On sloping land, the tank is often called a hillside dam or just a farm dam. The excavation can be rectangular or square – with 3 or 4 walls – or circular.

The following guidelines are for rectangular, square and circular excavated tanks that do not require a civil engineer.

Why use hillside dams?

Hillside dams are a cost-efficient way of collecting and storing run-off water from winter rainfall where there is no easily accessible and suitable groundwater for pumping. Also, hillside dams avoid shallow saline watertables in the valley floors. Many of the soils in the south-west agricultural areas have sufficient clay content to provide a good seal. A disadvantage of hillside dams is that they have relatively large surface areas for the dam volume, and net evaporation rates in the dry summer are often greater than 1500 mm.

Recommended good practice

Depending on the type of excavated tank:

- choose the right design and construction for the site (see below)

- test and use clay soils that will seal the dam

- use improved catchments (roaded catchments)

- use silt traps (new page) and pipe inlets (design criteria below)

- use designed spillways for the silt trap and tank

- fence the roaded catchment, silt trap and tank to exclude livestock

- pump and reticulate from the tank to storage or watering points.

How hillside dams are used

Hillside dams are used:

- where filling is from a natural or improved catchment (grade banks or roaded catchment)

- where the front wall (upslope) of the structure is open or continuous with piped inlets

- for supplying single paddocks or drought-proofing whole farms

- for livestock water supplies

- for crop spraying water

- for domestic use on-farm

- for fire-fighting water supplies

- for aquaculture.

How hillside dams work

Hillside dams are most effective at holding water when the base and inside walls of the dam are sealed with clay of low permeability to minimise leakage, and when catchments are improved to increase and collect run-off. In many agricultural areas of Western Australia (WA), run-off from crop land and pasture is not adequate to reliably fill farm dams. Run-off can be improved by using grade banks and roaded catchments (Figure 1).

Conditions where these guidelines apply:

- on gently to moderately sloping land, for excavated tanks and hillside dams in agricultural and pastoral areas

- anywhere there is a requirement for initial or additional water supplies

- near to, but clear of, streams, creeks and rivers; positioned so that the overflow from the structure can be safely diverted to a stream, creek or river

- where a natural or improved (roaded) catchment is of sufficient area to fill the farm dam.

Types of dams

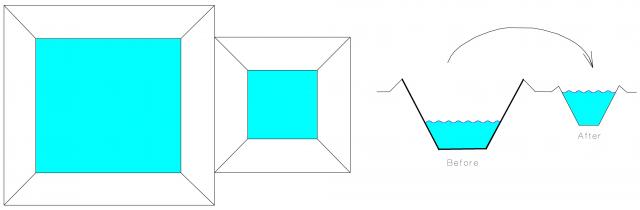

Rectangular or square excavated tanks with three or four walls

These are the most common type of farm dams in the agricultural areas of WA. Excavated tanks need to be constructed of clay or have a clay lining that is 0.7 to 1.0 m thick. A 3-walled excavated tank is open at ground level on the uphill, and the excavated soil is used to construct the 3 walls above ground with freeboard above the full supply level. Four-walled and round excavated tanks optimise capacity and minimise siltation.

Double dams

Double dams (Figure 2) are useful where watertables limit depth of a dam. The design reduces the loss of water to evaporation by having smaller and deeper excavations to limit the surface area relative to the volume. Evaporation reduction is particularly effective when the smaller dam is kept topped up by pumping from the larger dam.

Ring and turkey nest tanks

Ring and turkey nest tanks (Figures 3 and 4) are used on flatter sites where shallow saline watertables may be present. The base of the dam can be near ground level. Ring tank (Figure 4) walls are usually constructed from earth 'borrowed' from a ring inside the tank, with a centre 'island' at normal ground level. This type of tank is prone to leakage (there can be low levels of clay in the excavated soil) and high evaporation loss relative to hillside excavated tanks (the surface area relative to water volume is high).

Turkey nest dams consist of a completely enclosed earth embankment, which is filled by pumping from an alternative water source (i.e. a creek, groundwater or other smaller dams). These dams are usually sited as high as possible in the landscape so that water can be reticulated from them to other parts of the property.

The dams built in WA do not usually retain a mound of soil in the centre and are smaller than those in New South Wales and Queensland. Turkey nest dams require a site that is reasonably flat with good dam building clay not more than a metre below the surface; otherwise, the cost of overburden removal reduces the cost effectiveness of construction.

Turkey nest tank walls are constructed mostly from earth borrowed from outside the tank. The tank in Figure 4 has used this excavated area as a catchment, and the centre of the tank has been excavated to some degree. The milky blue colour is caused by suspended clay in the very fresh water. Water from this tank is pumped and reticulated to other parts of the property near Esperance.

Planning considerations

The Occupational Safety and Health Act 1984 sets objectives to promote and improve occupational safety and health standards. The Act sets out broad duties and is supported by more detailed requirements in the Occupational Safety and Health Regulations 1996.

The legislation is further supported by guidance material, such as approved Codes of Practice, through WorkSafe Western Australia. ‘Code of Practice – Excavations’ applies to all workplaces where excavation occurs and particularly when “a person is required to work in an excavated area or other opening in the ground that is at least 1.5m deep”. This is especially relevant to soil test pits and pipes in trenches.

Local government may have limitations on dam placement, especially in relation to roads and other infrastructure. For example, dams are not to be sited within 100 m of a watercourse or within 200 m of roads.

Guidelines:

- avoid sites close to and above buildings, work sites, roads, and valuable infrastructure

- avoid valley floors or drainage lines with shallow watertables; check options for reducing salt build up in dams

- allow space above the dam for improved catchment structures (grade banks or roaded catchments)

- calculate water needs for a full year in dry conditions

- calculate water flows and storage based on dry years, and for the intended improved catchment structures

- design inflow (silt traps, piped inlets) and outlets (outlet pipes, emergency spillway) to safely handle peak flows from intense storms

- design dam and water access to reduce erosion and allow for maintenance – we recommend that you do not have direct access by livestock

- use fewer, larger dams and reticulation to reduce evaporation losses and increase flexibility of water distribution.

Design criteria

Site characteristics are accurately measured with particular attention to site slope, topsoil depth, overflow disposal and available area of catchment/improved catchment.

Excavation site should be drilled, or test pits dug, to 1m below the proposed maximum depth of the excavation. Drill 1 hole through the centre and 4 holes – one in each corner – through the floor of the proposed structure. Take soil samples and note the presence of subsurface water, rock and gravel or sand seams.

Soil types at the construction site are field-tested and classified to ensure the stability of the proposed structure. Soil is field classified for engineering properties using the Unified Soil Classification System. Test with particular attention to dispersion, aggregation, cracking and grading.

Clay content is to be at least 25%.

Structure capacity is determined by assessing water requirements and catchment yield with consideration of evaporation and seepage.

Excavation shape is round, rectangular or square with consideration to having the embankment (wall/s) constructed continuously around the structure to reduce evaporation, control inflow and exclude paddock debris generated by severe storms. On flatter ground, consider using round dams, because this shape has the smallest surface area relative to volume for evaporation to affect.

Catchment peak flow run-off – where natural catchment is diverted into the dam, the peak flow run-off is determined using a recognised method, such as the Flood Index Method or the Rational Method. Usually 10 hectares of natural catchment, directed by grade banks, is appropriate for each 1000 m3 of storage. The peak flow run-off can be used to determine spillway dimensions. See Australian Rainfall and Runoff for more information.

Improved (roaded) catchment area is determined using daily rainfall data, catchment runoff threshold, and target dam volume.

Depth is adequate for providing sufficient water supplies and allowing for evaporation loss. Depth should be greater than annual evaporation, or greater than total evaporation for the chosen design period if the dam is for drought-proofing. Many sites are depth limited by saline watertables or other constraints. Common depth is 5–6 m and a volume of 5000–6000 m3.

Sideslope (batter) ratio is usually 3:1.

Freeboard is a minimum of 1m above the maximum water level.

Overflow – the crest is set at the maximum water level for the dam. Where a silt pit is installed, overflow can be set out from the silt pit. Overflow is to discharge clear of the dam walls. Where there is a risk of crest erosion, materials other than earth can be used; flumes and chutes are potential applications.

Use the Weir formula to calculate the crest width for the chosen overflow depth for a 1-in-20 to 1-in-50 year (return period) peak flow discharge. Calculations based on the greater return period are recommended for larger dams with large, natural or improved catchments. Chosen flow depth should be small enough that the dam freeboard is not compromised. Consult a specialist engineer or trained contractor for using this formula:

w = Q/(1.7h1.5)

where:

w = drop structure width across stream (m)

Q = design flow or crest capacity (m3s-1)

h = design depth of flow at crest (m)

Mechanical spillways, such as a pipe with hooded inlet or a riser, can be used to overflow the dam where frequent low flows could damage the constructed overflow. Top of the hooded inlet or riser is set at the maximum water level of the dam and to discharge clear of the walls. Without compromising the dam's freeboard, the main overflow crest can be set 0.1–0.15 m higher.

Pipes are 150 or 200 mm nominal bore PVC and have a debris shield, rack or strainer fitted to the inlet end of the pipe.

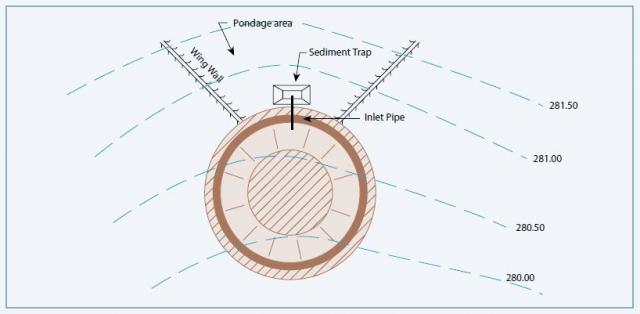

Piped drop inlet, sump inlet and headwall with inlet pipes are set out above the dam. Top water surface of the inlet is set at the maximum water surface of the dam.

Inlets are designed in such a way as to regulate surges of flow from high run-off events that would otherwise damage the dam. Trash rack or strainer screen should be installed to exclude paddock debris.

Inlet structures are constructed of concrete, sand bags, gabions or large diameter concrete pipes (up to 900 mm diameter installed vertically over inlet pipe ends). Inlet pipes are 150 or 200 mm nominal bore PVC.

To contain the approximate amount of run-off from a 10-year average recurrence interval (ARI) storm, one inlet pipe is required per hectare of natural and improved catchment. Up to 3 pipes are required to contain a 50-year ARI. The larger (200 mm) nominal bore pipes are used in agricultural areas with higher average annual rainfall.

Silt pit with inlet pipes is recommended on all new hillside dams.

Dams with roaded or improved catchments and less than 25 ha of farmland catchment should have a minimum of 250 m3 of pit storage for each hectare of roaded or improved catchment, and a minimum pit storage of 1000 m3.

Minimum of three 100 mm poly(black) or PVC (class 12) inlet pipes or two 150 mm poly (black) or PVC (class 12 minimum specification) inlet pipes.

Minimum of one 100 mm poly or PVC inlet pipe per hectare of roaded/artificial catchment or one150 mm poly or PVC pipe per 2.5 hectares of roaded or improved catchment.

Silt pit volumes ranging from 100 to 1000 m3 may be appropriate. There will be some loss of run-off through evaporation of water retained in the pit, as inlet pipes must be set above the settled debris and silt.

Pipe sizes and numbers are to be matched to inflows similar to inlets (above) and to be fitted with a trash rack or strainer screen.

Planning methodology – identify sites that may be suitable for a dam. Given water requirements, catchment/improved catchment run-off/yield, evaporation and leakage over a design period, calculate the structure capacity, shape and dimensions. Choose the layout of structure, catchment, inlet, outlet and safe overflow disposal.

Determine catchment/improved catchment dimensions and confirm site suitability by pegging layout.

Volume of completed structures needs to be confirmed by measuring and calculating the top, middle and bottom areas as well as measured depth. The formula for all excavated shapes is the prismoidal formula expressed as:

V = (A+4M+B)d/6

where:

V = volume

A = top area of excavation (area of water surface when full)

B = bottom area of excavation (area of floor)

M = area at ½ depth

d = depth

For convenient calculating, the following derivations of the prismoidal formula can be used for each excavated shape.

Circular:

V = π [R2+(R.r)+r2]d/3

Rectangular:

V = [(L.W)+(l.w)+[(L+l).(W+w)]]d/6

Square:

V = L2+(L.l)+l2]d/3

where in all formulae:

V = volume (m3)

R = radius of water surface (m)

r = radius of floor (m)

d = depth (m)

π = Pi or 22÷7 or 3.14159

L = length of water surface (m)

W = width of water surface (m)

l = length of floor (m)

w = width of floor (m)

d = depth of water from surface to floor (m)

Volume of water in older dams

See calculating farm dam water volumes for a guide.

Safety and environmental aspects

Before construction, consult the local government authority, neighbours and, where needed, a specialist engineer or trained contractor. Take care in siting and constructing farm dams to avoid the risk of injury to people and damage to property or infrastructure. Failure of dam walls can lead to flash flooding. Eroded material from poorly planned, constructed or maintained structures can reduce flow capacities when deposited in downstream channels.

Legal aspects – Statute and common law

Interference with a watercourse in a proclaimed surface water management area is controlled under the provisions of the Rights in Water and Irrigation Act 1914 (WA). In certain circumstances excavated tanks or hillside dams may need a licence so check with the Department of Water and Environmental Regulation to see if your excavated tank or hillside dam needs a licence.

Local government councils often require their Chief Executive Officer is notified of proposals to construct farm dams near road reserves or land vested in the shire council.

Common law rules govern the flow of surface water discharged into watercourses. To reduce the likelihood of cross-boundary disputes:

- construct water-impounding structures so they do not have a detrimental effect on streams further down the catchment

- take reasonable steps to ensure the safety of another person and another person's property

- consider what effect planned earthworks will have on other people and seek consent from any person that may be affected

- take care during construction and maintenance to stop the loss of disturbed material from the site.

Construction

- Prepare site by pegging and referencing corners (square and rectangular shapes) or centre (circular shape). Measure fall across the site for calculating any storage volume above the excavation. Install a temporary bench mark (TBM) in a protected location.

- Remove topsoil and stockpile clear of the embankment (wall) location.

- Excavate core trench under the embankments if pervious materials are present under the topsoil. Core trench must extend 1m into impervious material.

- Build the embankments by excavating in ‘floors’ and pushing material to the correct location. Compact the embankments with the bulldozer weight in 50 to 75 mm layers or compact 150 mm layers with a sheepsfoot roller. Embankment sideslope ratios can be confirmed by using an electronic builders slope finder or battometer.

- Install inlet and outlet pipes early in construction of the embankments.

- Construct the overflow and ‘final trim’ structure.

- Spread the stockpiled topsoil on the outside batters and embankment top. Topsoiling encourages vegetation and helps retain embankment moisture and resist cracking.

Operation and maintenance

- Inspect embankments for safety and seepage. Check for cracking and piping and movement cracks. Look for erosion of sideslopes, inlets and outlets. There are several treatment options for leaky dams.

- Clear drop inlet, sump inlet, inlet pipes and silt pits of debris and eroded material. Vermin can burrow into inlets, outlets, embankments and improved catchment. Burrows should be dug out and repacked with clay. Vermin around the structure should be eradicated.

- Consider fencing the dam and catchment where supply is an important or drought-proofing structure.

References

- Bligh, K J 1989, Soil conservation earthworks design manual, Department of Agriculture and Food, Western Australia.

- Clement, JP, Bennett, M, Kwaymullina, A & Gardner, A 2001, The law of landcare in Western Australia, 2nd edn, Environmental Defender’s Office WA (Inc), Perth, WA.

- Huffman, RL, Fangmeier, DD, Elliot, WJ & Workman, SR 2013, Soil and Water Conservation Engineering, 7th edn, American Society of Agricultural and Biological Engineers, St. Joseph, Michigan.

- Keen, MG 1998, Common conservation works used in Western Australia, Agriculture Western Australia, Western Australia.

- Keen, MG 2001, Field pocket book of conservation earthworks formulae and tables, Department of Agriculture, Western Australia.

- Lewis, B 2002, Farm Dams, Land Link Press, Collingwood, Victoria.

- WorkSafe Western Australia 1996, Code of practice: excavation, WorkSafe Western Australia, Perth.