Soil texture explained

Soil texture is an estimate of the amount of sand, silt and clay particles present in the soil. It is an inherent property of the soil and cannot be changed by normal agronomic practices.

Many physical characteristics of the soil depend on texture, and the clay content is very important. Soil texture affects drainage and structure, which in turn affect how plants will grow in the soil. The clay and organic matter help to bind soil particles together, forming stable aggregates, which are an indicator of good soil structure: good soil drainage, root and seedling penetration, and aeration.

Before you start

Step 1 Sieve your soil

Use a 2-millimetre (mm) sieve to remove stones and gravel, and break down lumps in the soil, making it easier to work with. If your soil is damp, you will need to dry it before sieving. To dry, place about 1 kilogram of broken-up soil in an oven at 150°C for 2–4 hours.

Step 2 Estimate percentage of stones or gravel in the soil

Make a visual estimate of the percentage of stones and gravel in the soil from step 1. This helps if you plan to estimate the plant available water capacity of the soil.

Hand texturing

Step 3 Take a small handful of soil

To fit comfortably in the palm of your hand.

Step 4 Add water to the sample

Add enough water to make a bolus or ball (Figure 1). Knead the bolus for 1–2 minutes, adding more water or soil until it just stops sticking to your fingers. Note how the soil feels when kneading it: gritty (sandy), silky (silty) or plastic/sticky (clay). If you can’t make a bolus, the soil is very sandy.

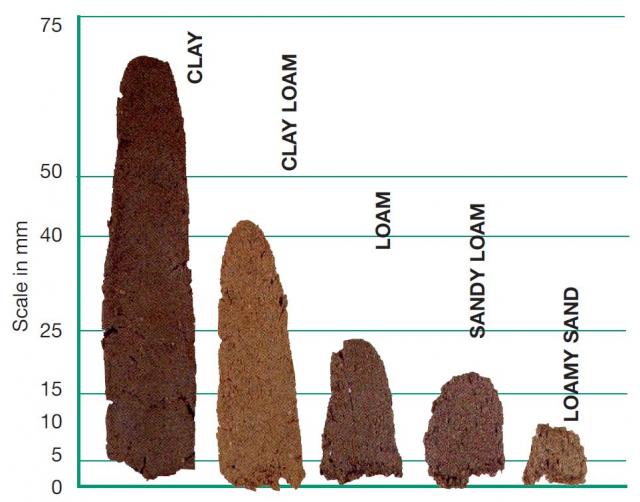

Step 5 Form a soil ribbon

Gently press out the soil between your thumb and index finger to form a hanging ribbon. The ribbon should only be 2–3mm thick. The more clay you have in your soil, the longer your ribbon will be (Figures 2 and 3).

Use information in Table 1 to more accurately identify your soil’s texture.

Field texturing is not as accurate as laboratory testing for particle size: field textures are influenced by organic matter, different clay minerals, the sodicity (i.e. the proportion of sodium on the cation exchange sites of the clay) and the amount of calcium carbonate (lime) present.

In general, field texture is a reasonable guide to soil behaviour for crop and pasture agronomy. More information to help you texture a soil sample is given in Tables 1 and 2.

| Texture grade | Behaviour of moist bolus (the way a soil feels and the ribbon formed when manipulated by hand) | Approximate clay content | Soil code |

|---|---|---|---|

| Sand | Coherence is nil to very slight; cannot be moulded; single sand grains stick to fingers | Less than 5% | S |

| Loamy sand | Slight coherence; can be sheared between thumb and forefinger to give minimal ribbon of about 5mm | About 5% | LS |

| Clayey sand | Slight coherence; sticky when wet; many sand grains stick to fingers; discolours fingers with clay stain; will form minimal ribbon of 5–15mm | 5–10% | CS |

| Sandy loam | Bolus is coherent but very sandy to touch; dominant sand grains are of medium size and are readily visible; ribbon of 15–25mm | 10–20% | SL |

| Loam | Bolus is coherent and rather spongy; no obvious sandiness or silkiness; will form a ribbon of about 25mm | About 25% | L |

| Sandy clay loam | Strongly coherent bolus; sandy to touch; ribbon of 25–40mm | 20–30% | SCL |

| Clay loam | Coherent plastic bolus; smooth to manipulate; will form ribbon of 40–50mm | 30–35% | CL |

| Clay loam, sandy clay | Coherent plastic bolus; sand grains visible in finer matrix; sandy to touch; ribbon of 40–50mm | 30–35% | CLS |

| Light clay | Plastic bolus; smooth to touch; slight resistance to shearing; ribbon of 50–75mm | 35–40% | LC |

| Light medium clay | Slight to moderate resistance to ribboning shear; ribbon of about 75mm | 40–45% | LMC |

| Medium clay | Smooth plastic bolus; handles like plasticine, and can be moulded into rods without fracture; moderate resistance to ribboning shear; ribbon of 75mm or more | 45–55% | MC |

| Medium heavy clay | Handles like plasticine; moderate to firm resistance to ribboning shear; ribbon of 75mm or more | 55% or more | MHC |

| Heavy clay | Handles like stiff plasticine; firm resistance to ribboning shear; ribbon of 75mm or more | 55% or more | HC |

| Coarse sandy | Coarse sand is obviously coarse to touch. Sand grains are readily seen with the naked eye |

| Fine sandy | More than 35% very coarse sand and very fine gravel between 1 and 3mm |

| Gritty | 35–70% by volume gravel |

| Stony | 35–70% by volume stones |