Boom sprayer loading guidelines – standard order of mixing

When loading the sprayer, it is critical to follow standard mixing order. Only deviate from this mixing order if there is a specific directive on the label of a key component of the mix.

- Fill your tank at least two thirds with water which is suitable for all of the components of the proposed mix, that is, no pH, hardness, clay or other limitations.

- Add water conditioners, for example, pH adjusters, ammonium sulphate.

- Add granules/flowables/powders and mix well. It is best to apply these to the top of tank so that they disperse with plenty of water. Granules require time to separate and disperse, for this to happen good agitation is needed. Granulated products which disperse when added to the tank can cause the most problems if products such as undispersed ECs, for example, trifluralin or crop oils are mixed with undispersed granules. The granules may not disperse and so will block the filters. Allow 5-10 minutes for the granules to disperse before adding other types of products.

- Add ECs and crop oils and mix well. If loading with a pre-mix pot, ensure good water movement so that the chemical is rapidly dispersed.

- Add water solubles, for example, glyphosate, amines. If you are using liquid fertilisers as carriers, very good agitation is essential and this will stop products like trifluralin from separating from Flexi-N®.

- Add wetters.

- Top up with water, mix well and apply the mixture as soon as possible.

Increase spray volumes for complex mixes

For most situations 50L/ha is quite satisfactory. For complex mixes, that is, those of three products or more, additional water, may be needed to help stabilise the mix. A rough rule of thumb is to increase the sprayed volume by 10L/ha for each additional product after three or four products have been added. This includes non pesticide items such as trace elements.

Even with adding extra water, blockages may still occur if you have self cleaning filters. These filters can return any unfiltered material, for example, undissolved granules, into the tank where it can build up causing blockages. If you know that your tank mix has some problems with precipitation or sludge/scum formation, or you are using granulated pesticides, consider cleaning out the tank after every third load.

Setting up your sprayer

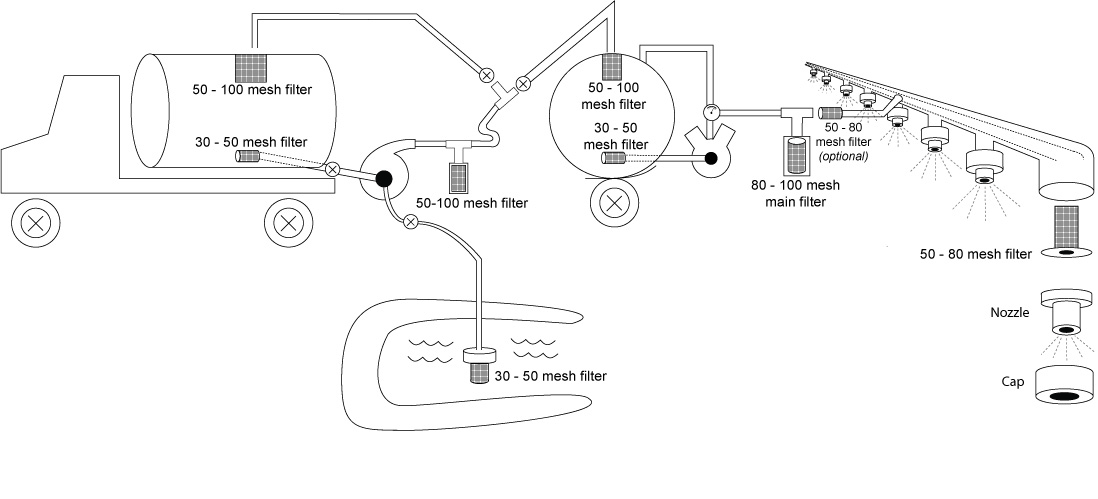

Simple attention to the set up of the boom sprayer will reduce the chances of blockages occurring. All products including water should be filtered into the tank and even if you have correctly followed the guidelines for mixing pesticides, in some cases, the combinations of wetters, oils, and dispersants of a complex mix can still result in filter blockages. Chances of getting blockages due to spray mixes can be reduced by ensuring correct filter sizes in the boom rig.

Correct filter sizes in your boom rig

- General tank filling: 50-100 mesh filter- to remove foreign material and lumps of wettable powders. Filling filters need to be able to keep out fine sand and can be finer than the main filter.

- Suction line to pump in-line filter: 30-50 mesh filter - to keep foreign matter out of the pump. Partly dispersed granules should be able to pass through this filter and be returned to the tank after travelling through the pump and hopefully broken up.

- Main filter: approximately 80-100 mesh filters - all filters downstream in the boom lines should be coarser than this filter. It should be a self cleaning large-capacity filter.

- Boom section filters: usually 50-80 mesh - are safety filters only and should not be finer than the main filter (otherwise, they will block up first). These filters are fitted to provide secondary protection for nozzles from any material escaping from the main filter due to breakage or when the main filter is cleaned. Note that boom sections should be cleaned occasionally to remove any sediment, for example, settled powders to stop the boom sections progressively blocking up from the end furthest from the inlet as powders settle out.

- Nozzle filters: usually 50-80 mesh - but this filter size depends on the nozzle size and the type of product being used. These can be removed if they keep blocking. The only role of nozzle filters is to keep nozzles from blocking from scale or dirt originating in the boom lines.