Types of inoculants

Inoculants come in four different carriers:

- peat

- freeze dried powders

- granular

- a pre-coated seed form, with inoculum as part of the pellet.

All forms of inoculant carry live cells of rhizobia and must be stored correctly to preserve high numbers. The shelf life of these products varies from several weeks in the case of some pre-coated seeds to three years for the freeze dried powder.

The cost of inoculation can vary from $5-25/ha depending on the product. Peat-slurry is the cheapest form of inoculant to purchase but there are additional costs in time and labour to consider. The more expensive options can be easier to use and offer greater flexibility for sowing operations.

Peat-slurry inoculants

For traditional peat-based carriers, the inoculum is applied as a slurry to the seed coat so that rhizobia are in direct contact with the seed. Packet size of inoculant is generally 250g and this amount is recommended to treat between 10-50kg of pasture seed (Table 1). When seeding mixtures of different pasture legume seeds, each cultivar should be inoculated separately and then mixed together.

| Inoculant group | Common name | Scientific name | Seed size | Maximum weight of seed to be treated |

|---|---|---|---|---|

| AL | Lucerne | Medicago sativa | Small | 25kg# |

| AL | Strand medic | M. littoralis | Small | 25kg |

| AM | Burr medic | M. polymorpha | Medium | 50kg |

| AM | Barrel medic | M. truncatula | Medium | 50kg |

| Bis | Biserrula | Biserrula pelecinus | Small | 10kg# |

| B | White clover | Trifolium repens | Small | 25kg |

| B | Strawberry clover | T. fragiferum | Small | 25kg |

| C | Balansa clover | T. michelianum | Small | 25kg |

| C | Persian clover | T. resupinatum | Small | 25kg |

| C | Gland clover | T. glanduliferum | Small | 25kg |

| C | Arrowleaf clover | T. vesiculosum | Small | 25kg |

| C | Subterranean clover | T. subterraneum | Medium | 50kg |

| C | Rose clover | T. hirtum | Medium | 50kg |

| C | Crimson clover | T. incarnatum | Medium | 50kg |

| C | Bladder clover | T. spumosum | Medium | 50kg |

| S | French serradella | Ornithopus sativus | Medium | 50kg |

| S | Yellow serradella | O. compressus | Medium | 50kg |

| Sulla | Sulla | Hedysarium coronarium | Medium | 10kg# |

# Pasture legume requires higher inoculation rates because of either small seed size, poor survival of rhizobia during inoculation or sensitivity of the symbiosis to low pH soils.

Peat-slurry inoculants (continued)

Adhesive solution

Pasture seed inoculants do not have adhesive glue mixed with the peat, unlike those for grain legumes. An adhesive solution must therefore be prepared separately before inoculation, to stick the inoculant to seeds.

After inoculation the coat is often dried with lime for ease of handling and to protect rhizobia against the effects of acidic fertilisers such as superphosphate and acid soils. Store peat cultures away from direct sunlight or heat; refrigerate, but don’t freeze the cultures. Discard packets past their expiry date.

Preparing adhesives

Adhesives include methyl-celluloses such as Methocel®, which is used at a concentration of 0.5%, and Seedstick™ which is used at 10%, although both are diluted for inoculating pods. Use rainwater where possible and use clean equipment.

To prepare 1L of adhesive solution (or slurry):

- Sprinkle the appropriate quantity of the granulated powder on to 200mL of near boiling water, stirring vigorously, until powder is dispersed (the use of a stirrer attached to an electric drill is very effective). Mix 5g powder for a solution of 0.5% final concentration of Methocel®, or 100g powder for a solution of 10% final concentration of Seedstik™.

- Slowly add 800mL of cold water while still stirring vigorously, until an even gel is produced.

- Allow the mixture to cool (preferably overnight) before adding inoculum.

Lime pelleting

Most pasture legume seeds should be lime pelleted using agricultural lime following inoculation with the peat slurry and adhesive. The exceptions are French and yellow serradella, which have the most acid tolerant rhizobia. Do not use slaked or hydrated lime because these are too alkaline and will kill the rhizobia. If required, serradella seed that has been slurry inoculated can be dried-off with clay or finely ground gypsum (4kg to every 50kg of seed) but not lime.

The proportions of adhesive solution, inoculum and lime are dependent on seed size and the concentration of adhesive. Table 1 groups the most common species of pasture legumes according to seed size, together with the appropriate Group of inoculum.

Details of inoculation methods

General guidelines for inoculation are provided in Table 2 but preparation of trial batches is recommended. Special considerations need to be made for biserrula (higher rate of inoculum) and serradella (clay/gypsum but not lime). French serradella sold in the pod or yellow serradella sold in enhanced pod form need special treatment (see below).

| Seed size (see Table 1) | Materials required for 50kg of seed or pod, peat inoculum | Methocel® (0.5%) | Seedstik™ (10%) | Lime | Seedcote |

|---|---|---|---|---|---|

| Small seed | Two packets | 2L | 2L | 4kg | 10kg |

| Medium seed* | One packet | 2L | 2L | 4kg | 10kg |

| Biserrula and Sulla seed | Five packets | 2L | 2L | 4kg | 10kg |

| Serradella pod | One packet | 6L at 0.16% | 6L at 3.3% | none | 12.5kg |

Prepare the adhesive solution first, then mix the inoculum with the solution, pour the mixture over the seed and stir vigorously until all the seed is wet. Higher rates of solution may be required if seed is dusty or there is a lot of sand or other fine particles. Add lime immediately after inoculation and mix until the seeds are evenly coated (see Figure 1).

Do not use too much lime because seeds will not flow easily through seeding machinery. Likely causes of poor lime pellets include:

- Powdery, soft pellets indicate either too much lime or uneven mixing.

- Pasty-looking pellets with the seed surface exposed indicates too much adhesive solution. Add more lime.

- Small seed clumps may be caused by excessive adhesive that may not break down after adding lime. Minimise this by rubbing the clumps against the side of the revolving drum.

- Hard, glossy, smooth pellets indicate too little lime or too much mixing after adding lime.

Seed can be processed in a cement mixer, by shovelling on a cement floor, or by using a revolving drum. You can also use a tarpaulin, mixing or rolling the seed by lifting alternate corners of the tarpaulin and walking forward. For bulk seed, some growers have developed systems that are based on using augers; however the incorporation of lime can be difficult and can cause blockages.

Inoculating serradella pods

Serradella pods absorb a considerable amount of liquid so larger volumes are required. To inoculate 50kg of pods, prepare two litres of a 0.5% of Methocel® or 10% Seedstik™ solution combined with one standard 250g pack of inoculum Group S. Add water to increase the slurry to six litres, and then mix the slurry with the seed.

An auger system for inoculation of serradella pods is possible since no lime is required. Introduce liquid under low pressure to ensure adequate coverage of the pods. Allow the serradella pods to dry overnight before sowing; otherwise the pods will not flow easily through seeding machinery.

Seed preparation and sowing

Peat-inoculated seed should be drilled into moist soil as soon as possible after inoculating because a delay in sowing leads to increased death rates of the rhizobia. If this is not possible, the inoculated seed must be stored under cool, dry conditions.

Aerial or dry sowing peat-inoculated seed should be avoided because it will result in rapid death of rhizobia and sub-optimal nodulation. Note that seed treatment with pesticides and fungicides is not recommended where seed is to be peat-slurry inoculated because this can be harmful to the rhizobia.

Freeze dried soluble legume inoculant

Inoculants containing freeze-dried rhizobia are available as soluble powders in 30g glass vials. They become active when the powder is reconstituted with liquid. The product also comes with a pack of protecting agent, which assists rhizobial survival during planting. A vial will treat between 25-200kg of pasture seed depending on the species.

These products allow for spray application, as their formulation is a suspension, and can be directly injected into the seeding furrow or the seed can be coated immediately prior to planting (without adding lime).

Treated seeds need to be drilled into moist soil within five hours of application. Avoid contact with pesticides and fungicides. These products have a shelf life of up to three years when stored at between 4°C and 10°C and not opened.

How to apply freeze dried inoculant

Remove cap and rubber bung from the glass vial, add water, replace bung and shake to dissolve the powder until all the powder is dissolved. For liquid injection add the vial of inoculant solution to 2L of cool water containing protecting agent.

Add this solution to the spray tank and deliver between 50-200L of clean water per hectare into the furrow during pasture sowing. To coat seed add dissolved solution from the vial into 2.5L of water (containing protecting agent) until evenly coated. Allow to dry before seeding.

Granular inoculants

Granular inoculants are stand-alone products that can simplify the delivery of rhizobia to the seed. The technology is an alternative to the labour intensive slurry mix-lime process and can provide greater flexibility in sowing operations (such as sowing ahead of rain). Note that dry sowing can increase the risk of establishment failure from false breaks of season.

The physical separation of the rhizobia from the seed also allows insecticides and fungicides to be applied to the seed, which would otherwise be damaging for the rhizobia. Granules are manufactured from either peat or clay and must be drilled with the seed to ensure rhizobia are placed in close proximity to the seed (Figure 2).

The Group types for each pasture species are the same as for peat-slurry inoculants (AM, AL, B, C, S - see Table 1). When sowing mixtures of legumes, the full rate of granular inoculant for each Group should be used. Avoid contact with free water when sowing seed with granules.

Clay-based granules

Clay-based granules are normally applied at 8-10kg/ha when sowing on 18cm row spacings. The granules should preferably be mixed with the seed at sowing, or distributed through a third box and drilled with the seed.

Excessive auguring should be avoided to minimise dust. They are particularly effective in coarse textured soils and higher rates are recommended for fine textured soils. Clay-based granules are air dried and can be stored for over six months without refrigeration. Store granules in a dry, cool area away from direct sunlight.

Peat-based granules

Peat-based granules are normally applied at 6kg/ha when sowing on 18cm row spacings. These granules must be stored in the same manner as peat cultures (with refrigeration), and sown with seed into moist soil. Do not mix granules with fertiliser.

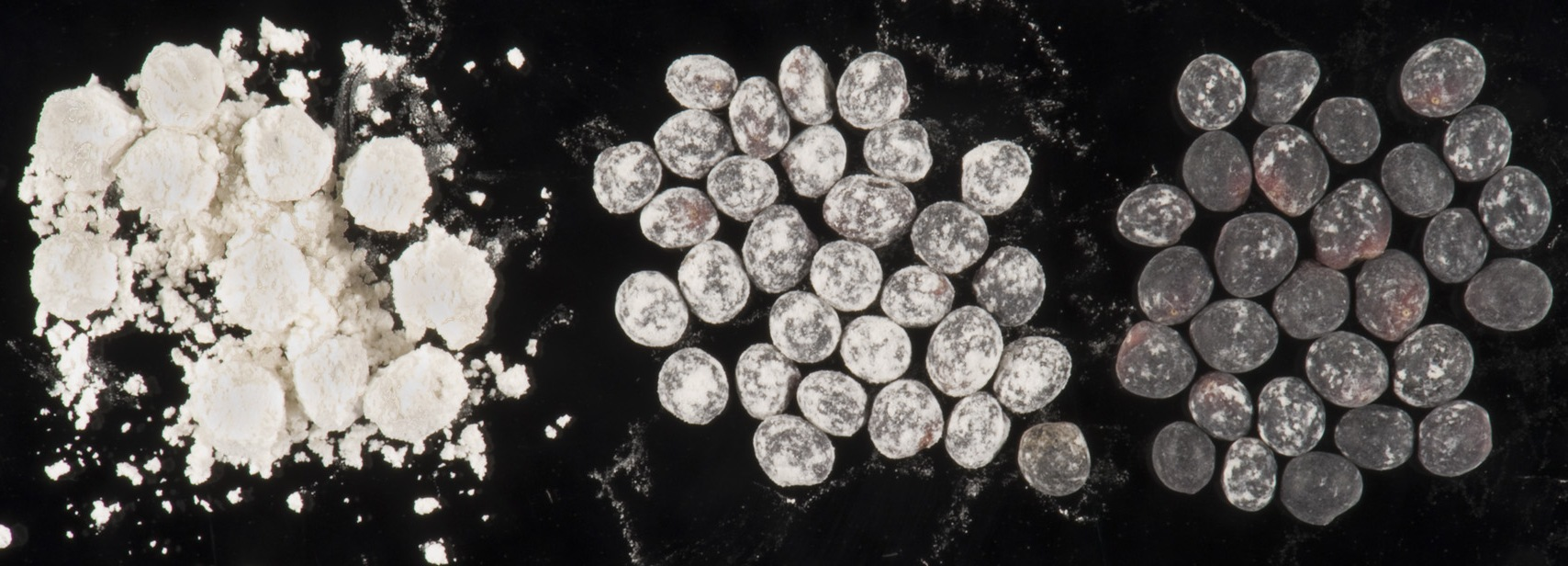

Pre-coated seed technology

Some seed companies sell pasture seeds that contain rhizobia as part of a complex seed pellet, which may also include insecticides, fungicides and micro-fertilisers. The main use of pre-inoculated seed is for lucerne and annual medics, because the rhizobia for these species survive well in this form. If purchasing pre-coated seed for clovers, serradella and biserrula, ensure the seed has been freshly coated, as rhizobia for these species will die to low levels after three weeks.

Inoculant quality control

Purchase inoculants that have been passed through an independent control system for a guarantee of quality. The Australian Inoculants Research Group, formerly known as the Australian Legume Inoculant Research Unit, conducts independent testing of inoculant quality and certifies acceptable products with a registered trademark.

Interaction between nodulation and nitrogen fertiliser

Nodulation and nitrogen fixation can be reduced if high rates of fertiliser nitrogen are applied with the seed or there are high soil nitrate levels. Added starter nitrogen should not exceed 10kg N/ha for new legume sowings.

Please consult product guides for specific technical information and instructions for use.

Acknowledgements

Information provided here has been produced from research partly funded by the Grains Research and Development Corporation through the National Rhizobium Program to support inoculation technologies.