Introduction

This page describes the consequences of mechanical damage and bruising to ware potatoes and how it affects their quality. Ways to minimise damage to tubers and how to assess whether your potatoes are being handled appropriately during harvest and washpacking are described.

When the skin of a potato is broken and bruised, the cells below are damaged and the tubers deteriorate because:

- entry of pathogens becomes easier

- water loss from the tuber increases.

This damage can have severe consequences.

Types of damage

Bruising

There are two types of potato bruises: blackspot and shatter bruise. Blackspot bruise (see Figure 1) involves damage to the tuber’s cell contents and requires the tuber to be peeled to be visible.

Shatter bruise (Figure 2) involves damage to cell walls and breaks in the skin, visible as cracking on the tuber surface. Shatter bruise can extend to the centre of the tuber and the broken skin is an ideal entry point for disease.

Skinning

Skinning is most often seen in potatoes harvested before the skins have fully matured. Abrasion between tubers, or between tubers and soil clods or grading equipment, loosens and removes the outer layer of skin. The shelf life of these tubers is reduced because diseases can enter easily and shrivelling is likely due to high water loss.

Factors influencing damage at harvest

Four factors influence the amount and severity of bruising.

Machinery maintenance and operation

The most important factor influencing bruising is the ratio of ground speed to conveyor speed. Bruising is minimised when conveyors are kept full of potatoes.

Increasing ground speed by shifting the tractor transmission to a higher gear can speed up harvest, increase and smooth out the flow of tubers and reduce damage. Individual conveyors are often at the wrong speed relative to the preceding or following conveyor. Harvester and washpack operators should be trained in management of equipment to reduce bruising.

Level of tuber impact

The greater the drop height, the more bruising that occurs. This also leads to a shift in damage from blackspot to shatter bruise. Long impact durations and low velocities - small bumps along the conveyor - result in blackspot and internal crushing, while short impacts and high velocities - drops from the elevator to the bunker - result in internal shattering.

Multiple low energy impacts also cause damage, although not as much as one large impact. Contact between potatoes holds less risk than contact between potatoes and machine parts.

An integrated approach is required to maximise the percentage of bruise-free potatoes. This involves harvesting as close to ideal temperature and soil moisture conditions as possible, while matching the volume of material flowing through the harvester to its capacity. The same approach should be applied to washpacking operations.

Soil and tuber conditions

Soil moisture, temperature and soil type influence the severity of bruising, as does tuber hydration, temperature and specific gravity. See Managing temperature in potatoes to improve quality for more details.

Reducing damage

Bruising and damage prevention in ware potatoes begins with careful planning before planting.

Paddock selection

Potato crops should be grown in soil that will produce fewer bruised tubers. Avoid rocky and cloddy soils which cause a lot of damage during harvesting.

Soil moisture

Irrigation prior to harvesting is very important in increasing the soil moisture content in clay soils. This reduces the number of clods and provides a layer of wet soil between the tubers and machine components, reducing impacts and consequent damage. On sandy soils, manage moisture so soil will not separate from the conveyor thereby increasing tuber damage. If soil is too wet, delay harvesting. Soil moisture for harvest should be between 60 and 80% of field capacity.

Skin maturity

Allow two to four weeks after top removal for skins to harden. Maintain soil moisture so tubers do not dehydrate underground while the skin is hardening.

Temperature

Tuber temperatures between 12 and 18ºC are considered ideal for harvesting as this is when less bruising occurs and microbial growth is not too fast. Tubers warmer than 18–20°C and under drought stress are susceptible to blackspot bruising.

Harvesting when tuber pulp temperature exceeds 18°C or soil temperature is greater than 25°C increases the risk of microbial rots, especially in damaged tubers. Tuber temperatures should also be kept within the optimum range during washpacking.

Harvester and washpacker set-up

Potato harvesters have many adjustments to allow gentle handling. Set-up can be assessed using an electronic potato (instrumented sphere).

Assessing set-up

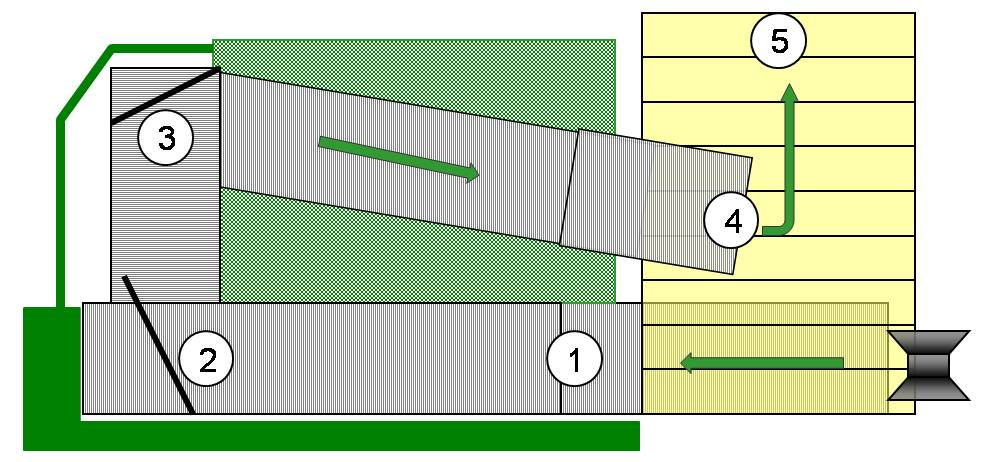

Assessment of impacts during harvesting can be measured using an electronic potato such as a Smart Spud®. The Smart Spud (produced by Sensor Wireless Inc) contains an accelerometer that measures impacts as G-forces as it passes through handling equipment (see Figures 3 and 4).

G is a measure of gravitational units where 1G = 9.81m/s2. The higher the level of G-force, the more severe the impact. By burying the Smart Spud in the ground it can be lifted with other tubers and pass through the harvester. This allows you to identify specific locations where damage is occurring. Similarly, the Smart Spud can be placed in a potato line to determine impact points through the washpacking process.

Results from calibration of WA potato varieties against G-force readings from the Smart Spud show differences in bruising occur with drop height, variety and temperature (Table 1).

At 10°C, 20% of Nadine tubers were damaged from a drop of 40cm. Ruby Lou was more tolerant at this temperature with no bruising. Bruising in Ruby Lou only started at 60cm with 30% of tubers bruised.

| Drop height (cm) | Mean G-force (G) | Ruby Lou % tubers damaged at 10oC | Nadine % tubers damaged at 10oC | Ruby Lou % tubers damaged at 15oC | Nadine % tubers damaged at 15oC | Royal Blue % tubers damaged at 15oC |

|---|---|---|---|---|---|---|

| 10 | 52 | 0 | 0 | 0 | 0 | 0 |

| 20 | 102 | 0 | 0 | 0 | 0 | 5 |

| 30 | 164 | 0 | 0 | 0 | 0 | 10 |

| 40 | 194 | 0 | 20 | 0 | 0 | 20 |

| 50 | 218 | 0 | 80 | 0 | 0 | 35 |

| 60 | 223 | 30 | 60 | 70 | 90 | 40 |

| 70 | 226 | 40 | 60 | 20 | 70 | 80 |

| 80 | 232 | 30 | 100 | 20 | 90 | 80 |

| 90 | 279 | 50 | 90 | 30 | 90 | 80 |

| 100 | 244 | 40 | 100 | 30 | 100 | 80 |

At 15°C, a 20cm higher crop was required for Nadine to show bruises but here 90% were affected. Bruising in Ruby Lou again did not occur below at 60cm drop height but at the higher temperature the bruise percentage at 60cm was more than double that of the lower temperature.

Royal Blue tubers at 15°C were susceptible to bruising at lower drop heights than Ruby Lou and Nadine, with 5% of tubers damaged at just 20cm.

Reducing drops and adding cushioning

Modifying equipment and decreasing harvesting and washpacking speeds can minimise damage. Reducing drop heights from conveyors will improve potato quality.

Considerable bruising can occur where drops are greater than 40cm, particularly when the drop area is on belting supported by a hard metal roller or plate.

The impact surface affects the amount of damage caused to a potato. Cushioning materials considerably reduce impact. A 6mm thick rubber layer on steel increases energy absorbance considerably, relative to uncovered steel. This means tubers are less likely to get damaged if mechanical components are covered in rubber.

Case studies in WA have found that an instrumented sphere will record higher impacts with greater drop heights and no cushioning. For example, from the elevator into the bunker, extremely high impacts (above 300G) have been recorded.

Recommendations

- Manage soil temperature and moisture by irrigating before harvest if soil is too dry or tuber temperature is above 18°C. See Manage temperature in potatoes to improve quality.

- Minimise bruising by keeping conveyors full of potatoes. Increasing ground speed by shifting the tractor transmission to a higher gear can speed up harvest, increase and smooth out the flow of tubers through the harvester and reduce tuber damage.

- Ensure the speeds of individual conveyors are matched to the speed of the preceding or following conveyor.

- Assess harvesting equipment and identify high impact areas with an instrumented sphere. Modify equipment accordingly.

- Lower the number and energy of impacts. Avoid excessive drop heights. Keep drop heights on harvesting equipment and bin filling to less than 40cm to prevent blackspot and shatter bruising.

- Use cushioning material where possible. Adding cushioning and removing steel at transfers can reduce impacts and related damage.

- Be aware of varietal susceptibility to bruising. Some varieties are more tolerant than others and machinery and operations should be set up accordingly.

Acknowledgments

This work was undertaken as part of the Horticulture Australia Ltd project PT06047 Improving the visual and internal quality of WA ware potatoes to meet consumer needs, managed by Western Potatoes Pty Ltd.