Raised beds can increase crop yields on waterlogged sites

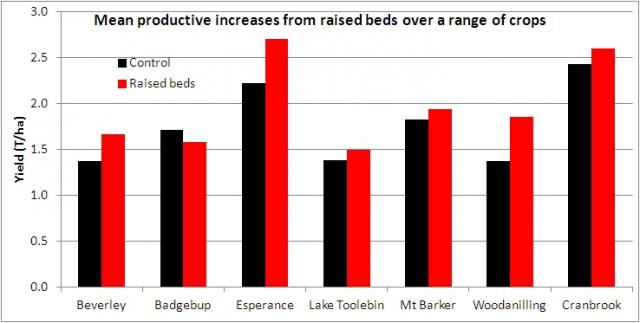

Substantial increases in grain production have been achieved in most areas from paddock-scale research sites located across a wide range of soil types in the south-west of Western Australia. These sites ranged from Beverley to Esperance, and included soils that ranged from grey loam over clay, to gravelly sand over clay, to sand over clay (Figure 1).

Grain yield increased by an average of 0.47 tonnes per hectare (t/ha) on research sites in 1997–2001 across a range of crops (oats, wheat, peas, lupins and canola).

These production increases were achieved during drier than normal seasons and from some areas where the long-term frequency of daily waterlogging during July is predicted to be less than 50%. This means that in wetter seasons and on more-waterlogged sites, increases in yield can be expected to be higher.

Growers who have adopted raised-bed farming have obtained similar yield increases from:

- sand over clay and gravelly sand over clay soil types

- normal to slightly wetter than normal seasons

- barley, wheat, canola and lupin crops.

Why use no-till on raised beds?

Successful cropping on raised beds requires:

- no-till crop establishment to avoid disturbing the raised bed

- agronomy suited to the bed and furrow configuration.

No-till benefits on raised beds are:

- retention and build-up of the organic matter of roots and their associated soil organisms to stabilise weak or dispersible soil structure

- retention of the large pores created by roots and their associated organisms to enhance rapid infiltration and aeration of the root zone

- retention of the roots as ‘reinforcing rods’ to minimise or prevent subsidence of the raised beds in wet conditions

- minimal disturbance and movement of soil during seeding – this reduces the need to reshape beds to their original height and width

- better weed control by minimising inter-row soil disturbance and germination.

There are good reasons to occasionally have more soil disturbance at seeding:

- to control diseases like rhizoctonia bare patch, some of the septoria diseases, black spot in peas, ascochyta in faba beans and blackleg in canola

- to incorporate root-active herbicides, such as trifluralin

- to mix fertiliser with soil close to the seed and minimise the risk of ‘fertiliser toxicity’ damage to germinating seeds.

Crop management on raised beds

Raised beds are usually 1.83 m from centre to centre of the mounds, with furrows 0.45 m wide (Figure 2). These measures can vary according to the cropping machinery being used, CTF spacings and the cost of any adaptations to machinery.

Newer machinery may have 3 m centres for wheel tracks and 0.6 m wheel widths. For this spacing, mounds will be 2.4 m wide and furrows will be 0.6 m wide, which will result in:

- less root-zone drainage

- less soil excavated from furrows resulting in lower bed height

- increased water flow along furrows because fewer furrows have to carry more water.

As beds get wider and shallower, the benefits reduce. Therefore beds not used for machinery traffic are still recommended to be 1.83 m wide.

Because of the furrows and beds, special cropping management is needed.

Furrows

Do not seed or fertilise in the furrows. Furrows are likely to be severely waterlogged or flooded during winter. Furrows may need to be regularly cleaned to control weeds and silt build-up.

Row spacing, seeding and fertiliser rate

We recommend the seed and fertiliser rate that would normally be applied per hectare on level ground, be applied only on the beds. The options are to:

- keep the row spacing the same and increase seeding rate and fertiliser rate in the rows

- keep the seeding rate and fertiliser rate the same, and use narrower row spacing.

These give the same yield in most situations, but the narrower spacing has some problems:

- Narrow spacing on raised beds makes seed depth control highly dependent on the speed of sowing. At speeds greater than 8 kilometres per hour (km/h) with 20 cm row spacing, soil can be thrown by the trailing opener over the adjacent row, burying seed much deeper than intended. Keep sowing speed less than 8 km/h and check seeding depth regularly.

- There is reduced stubble clearance of seeders with rows spaced at 20 cm compared with 26 cm.

Rotations

Use the same rotations as for standard cropping. Because machinery tracks in the furrows, there may be difficulties for crops requiring swathing or special stubble handling.

Fertiliser placement

Raised beds improve access on waterlogged sites, which improves the opportunity for mid-season fertiliser. Fertiliser should be placed precisely on the sown rows of crop on the beds, and not in the furrows. Fertiliser that lands in furrows is likely to be transported off-site and become a nutrient pollutant to streams and rivers: using liquid fertiliser and only spraying the mounds overcomes this problem.

Spraying

Spraying to control weeds, diseases and insects in crops on raised beds is the same as for crops grown on normal seedbeds.

Swathing and harvesting

All machinery wheel tracks must fit the furrows, otherwise they need to operate on specially constructed access tracks, cross-drains, or at the end of the field on the headland or catch drain. Swathing is possible with some adaptations.

Crops that need specific harvest planning

Crops that do not remain erect or which are harvested from swaths, such as field peas, swathed canola and barley, require some pre-harvest planning, particularly in relation to the timing of harvesting and the placement and width of swaths.

Field peas

Field pea crops must be harvested as soon as the grain is at or slightly above the maximum allowable moisture content to facilitate pick-up of the vine (Figure 3). Stems at or slightly above the maximum allowable moisture content retain some pliability, and a pick-up harvest front can lift and capture any vine that has slumped into the furrows.

If harvest is attempted after the crop has passed this stage, the stems will have dried to an extent that makes them brittle. A pick-up harvester front cannot lift pea vine in this condition. The stems break when lift is attempted and a considerable loss of grain can result from crop that has slumped into the furrows.

Using a crop desiccant can provide some operational flexibility to manage the condition of the crop at harvest.

Swathed canola and barley

Swathing must leave the swath on the top of a bed: adapt the swather’s opening to match the top of a bed. If a swath is not located squarely on top of a bed, some of it will fall into the furrows, yield will be lost, and drains will be blocked.

If a swath overhangs the furrows, lift and harvest when seed moisture content is at or slightly above the limit and the straw is still a little pliable: the swath will tend to lift without breaking apart.

Bed width can be adapted for large areas of swathed crops on raised beds. For example, a farmer in the Esperance district configured his bed-former to build a 2.5 m wide bed, in amongst beds that are 2 m wide, specifically to carry a swath and facilitate the harvest of the swaths.

Stubble management

Reduce the build-up of stubble in the furrows. Stubble in the furrows will impede water flow, creating waterlogged conditions in adjacent beds, causing the beds to subside and lose their improved infiltration and aeration properties. In large storms, furrow blockages may cause water to cover the beds and erode beds and channels.

Options to manage stubble on raised beds include:

- use stripper fronts on the harvester – this has several advantages in raised bed cropping:

- very little chaff and chopped straw left on the ground that may clog furrows

- can harvest cereals with tough straw

- harvest the crop high and subsequently harvest the stubble for straw, leaving erect stubble about 5 cm high

- harvest crops low, leaving erect stubble about 15 cm high and using a highly efficient straw storm on the harvester to spread small pieces of straw and chaff evenly

- trail a chaff bin behind the harvester to avoid leaving a trail

- leave a harvester trail that is subsequently baled or burnt

- graze stubbles after harvesting them low.

If stubble builds up in the furrows of raised beds, clear them with a furrower, either as a separate operation or at seeding. Furrowers can be mounted on the front of a seeder bar.