The most common irrigation system for vegetable production in the south west is semi-permanent overhead watering. Using drip irrigation can potentially lead to reduced water application without reducing yield. Drip irrigation may also decrease irrigation run-off and nutrient leaching, reducing erosion and nutrient losses into the environment.

The incidence of fungal diseases that can flourish in the moist environment created by overhead irrigation may be reduced by drip irrigation as the plant leaves are not wet. Drip irrigation can also reduce pumping costs due to lower running pressure. Ease of automation and the ability to schedule irrigation events with precision are further potential benefits.

Demonstrations of cauliflower crops watered using drip irrigation were conducted in Manjimup over two summers in 2012 and 2013. Both compared drip irrigation with overhead irrigation and were on karri loam soils at the Manjimup Horticultural Research Institute.

The drip irrigated plots received overhead irrigation for site preparation, including weed control, and on the day of transplanting, to reduce transplant stress and settle soil around transplants. After this time the drip irrigated plots only received drip irrigation.

Drip irrigation systems have potential for a range of vegetable brassica crops. A small area should be trialled before implementing a new irrigation system on a large scale.

Summary of results

In the 2012 crop, curd size and quality were similar between the drip irrigated and overhead irrigated plots. However, the drip irrigated plants tended to be greener, lusher and have more vegetative growth. They also matured slightly later.

The 2012 results were not repeated in 2013. The drip irrigated plots all produced lower yields with smaller curd size and lower quality. Plant size was also smaller. All drip-irrigated plots appeared to suffer from water stress.

It is unknown what caused the variability in results between the two seasons. However, there were longer and more extreme heatwave conditions early in the crop life in 2013. Sufficient water may not have been applied through the drip system to meet the needs of young plants with small root areas. Crop growth may have been set back from that time onwards.

If drip irrigation can produce equal quality and yield in the South West compared to overhead irrigation, then investment in drip irrigation may be worthwhile. Additionally, drip-irrigated plots used 25% less water when irrigated at the same rate as the overhead-irrigated plots. This was due to water only being applied to the root zone, not across the entire growing area.

Demonstration information

Equipment specifications

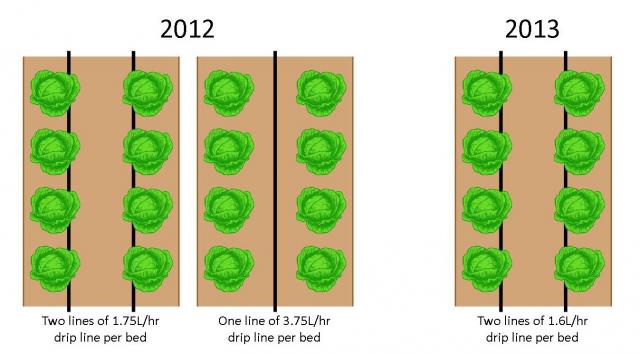

Both demonstration crops were grown on 1.7m wide beds with two rows of cauliflower per bed, giving 80cm between row spacing and 35cm within row spacing. Pressure compensated drip line with 30cm dripper spacing was used for both crops.

In 2012, two different drip line configurations were used, each with different emitter rates:

- Two lines of 1.75L/hr drip line per bed. Drip lines were aligned along each row of plants.

- A single line of 3.75L/hr drip line per bed. Drip line was aligned to centre of beds.

In 2013, one drip line and configuration were used:

- Two lines of 1.6L/hr drip line per bed. Drip lines were aligned along each row of plants.

Figure 1 is a schematic diagram of the drip line configurations used in both years.

The choice of drip line was based on soil type and infiltration rates. Optimum specification will vary depending on soil type, water-holding capacity, water infiltration rate, system set-up and intended use.

The variety Boris was used in both years.

Irrigation scheduling and fertilisers

Irrigation rates for all treatments were based on a percentage replacement of daily evaporation. For example, if a plot was being watered at 50% evaporation replacement and the evaporation for the previous day was 7.6mm then 3.8mm of irrigation would be applied.

In 2012, all plots received 100% evaporation replacement. In 2013, the overhead irrigated plot received 100% evaporation replacement and the four drip-irrigated plots received either 100%, 80%, 60% or a variable evaporation replacement rate.

The variable irrigated plot received the following rates based on crop growth stage and soil moisture readings:

- 0-2 weeks after transplanting – 80% evaporation replacement

- 2-5 weeks after transplanting – 50% evaporation replacement

- 5-7 weeks after transplanting – 80% evaporation replacement

- 7-9 weeks after transplanting – 100% evaporation replacement

- 9 weeks after transplanting to harvest – 120% evaporation replacement.

Overhead and drip-irrigated plots received the same fertiliser regime in both demonstrations. Liquid post-plant fertiliser was applied through a boomspray for overhead-irrigated plots while drip line plots received fertiliser through the drip line.

Soil moisture monitoring

Soil moisture sensors were placed under all plots with sensors located at 0-15cm, 15-30cm and 30-60cm below the soil surface.

In 2012, data indicated that soil moisture in the root zone was more constant when using drip irrigation. With overhead irrigation, soil moisture would peak with irrigation events then fall as water drained away.

The variation in soil moisture was much smaller under the two lines per bed drip plot and smaller again under the one line per bed drip plot. More consistent soil moisture could lead to more even growth of a crop as a stable growing environment is maintained.

In 2013, soil moisture sensors under the drip irrigated plots receiving 60%, 80% and 100% evaporation replacement all showed steady moisture levels followed by a decline in soil moisture below crop requirements at different crop stages. The points at which soil moisture started to decline indicated that water requirements of the crop had increased and were no longer being met.

Soil moisture in the 60% evaporation replacement plot began to decline four weeks after transplanting. Soil moisture in the 80% evaporation replacement plot began to decline six weeks after transplanting. In the 100% evaporation replacement plot, soil moisture did not start to decline until nine weeks after transplanting, just 10 days prior to the first harvest.

In 2012, the drip irrigated plot received 100% evaporation replacement for the life of the crop. This plot did not show any signs of soil moisture levels declining below the required level for healthy crop growth.

The soil moisture data gathered during these demonstrations allows estimates of water requirements at different crop growth stages. Crops generally require different amounts of water at different growth stages. Soil moisture data from the demonstration crops suggests that irrigation applied early in crop life may be reduced to 50% evaporation replacement. The water application rate would increase as the crop grows.

Irrigation application rate changes can be made with any irrigation system, so it is not necessary to install a drip irrigation system to reduce water use based on matching crop water requirements with crop age and evaporation.

Crop growth and yield

Crop health and growth was observed throughout crop life. Curd weight, quality and date of harvest were recorded for each plot at harvest. The results varied between 2012 and 2013.

2012 demonstration

During crop growth there was minimal signs of heat and water stress. A major concern before planting was the drip irrigated plots would not be able to withstand hot days without the cooling effect overhead irrigation provides.

About one week after transplanting there were several days of 35oC+ temperatures, and on the first hot day all plants in the drip-irrigated plots wilted severely. There was minimal wilting in the overhead-irrigated plots. All plants recovered well and were not visually affected by subsequent hot days and heatwaves.

There was minimal disease in all plots so no comparisons could be made.

Average curd weights were similar across all treatments, averaging between 990g and 1050g for marketable curds.

Overhead irrigation plots tended to mature earlier and peak harvest took place three to four days earlier than drip irrigated plots. The drip irrigated plants tended to be greener, lusher and had more vegetative growth than overhead irrigated plants. This could be due to luxury amounts of water and nutrients available to the plants. Larger plants did not lead to larger curds in the drip plots. In such a situation savings may be made in water and/or nutrient application without reducing yield.

Cauliflower roots were very good at accessing water and had different patterns of growth depending on the irrigation they were receiving. In plots with only one drip line the roots grew preferentially towards the centre of the beds, that is towards the drip line. It is not known if all varieties would be as effective at accessing water as the variety Boris.

2013 demonstration

Early in crop growth there were no visible differences between any of the drip-irrigated plots and the overhead-irrigated plots. Heatwave conditions were experienced about 10 days after transplanting and persisted for five days. At the time of the heatwave there was no wilting or other signs of heat or water stress in any of the plots. After the heatwave, the drip irrigated plots lagged in vegetative growth and were not as vigorous as the overhead-irrigated plots.

As the crop grew the drip-irrigated treatments progressively showed stress. The drip-irrigated plots started showing signs of water stress which corresponded with measured reductions in soil moisture. Plants were obviously smaller, with fewer and smaller leaves. The leaves were blue-grey compared to the green of the overhead-irrigated plots.

The plots receiving 100% evaporation replacement and variable drip irrigation rates produced larger plants than the 50% and 80% drip-irrigated plots. These plots also showed signs of stress two months after transplanting when compared with the overhead irrigated plots.

Smaller plants led to significantly smaller curds and lower yields for the drip-irrigated plots compared with the overhead-irrigated plot. More curds from drip-irrigated plots were also deemed unmarketable due to yellowing from exposure to sunlight. With fewer and smaller leaves, the drip-irrigated plants did not have sufficient vegetative growth to cover curds.

There was greater incidence of white blister infection in the overhead irrigated plots. White blister is spread by water and infection is more likely when leaves are wet. White blister did not impact on yield or quality in this cauliflower crop. It is a concern in broccoli crops where it can infect the head, reducing marketability.

There was more pest damage, particularly from diamondback moth (DBM), in the drip-irrigated plots. DBM will often target stressed plants first. The water stress may have made them more susceptible to insect attack, contributing further to reduced yield and quality.

Conclusion

These preliminary demonstrations have shown that drip irrigation of cauliflowers on karri loam soils in south-west Western Australia is possible.

The variable results between the two years highlights the need for further research into suitable irrigation system configurations and scheduling techniques that can reliably produce an economically viable crop across a variety of seasons.

Before undertaking any irrigation system changes, it is recommended that you consult with a certified irrigation designer.